Outline for “Linear Guideway Block”

| Main Heading | Sub-Headings |

|---|---|

| Introduction to Linear Guideway Block | Importance in mechanical engineering, Evolution of linear motion systems |

| Understanding Linear Guideway Block | Definition, Structure, Core working principle |

| Types of Linear Guideway Blocks | Flanged type, Square type, Slim type, Heavy-load type |

| Materials Used in Linear Guideway Block | Stainless steel, Carbon steel, Polymer coatings |

| Design Features of Linear Guideway Block | Preload system, Rolling elements, Sealing mechanism |

| How Linear Guideway Block Works | Load distribution, Friction reduction, Motion stability |

| Advantages of Linear Guideway Block | High precision, Smooth motion, Long lifespan |

| Common Applications of Linear Guideway Block | CNC machines, Medical equipment, Robotics, Semiconductor industry |

| Linear Guideway Block in CNC Machines | Role in accuracy, Influence on cutting efficiency |

| Linear Guideway Block for Robotics | Precision in automation, Contribution to AI-driven machinery |

| Installation of Linear Guideway Block | Tools required, Step-by-step process, Safety considerations |

| Maintenance of Linear Guideway Block | Cleaning techniques, Lubrication methods, Inspection checklist |

| Signs of Wear in Linear Guideway Block | Noise, Vibration, Reduced accuracy |

| Troubleshooting Linear Guideway Block Issues | Misalignment, Contamination, Overload |

| Comparing Linear Guideway Block vs Linear Bearings | Differences in load capacity, Applications suited for each |

| Linear Guideway Block and Friction Control | Rolling friction vs sliding friction, Lubrication role |

| Choosing the Right Linear Guideway Block | Load requirements, Speed factors, Environmental conditions |

| Customization Options in Linear Guideway Block | Coatings, Preload adjustments, Special dimensions |

| Future of Linear Guideway Block Technology | Smart sensors integration, AI-powered diagnostics |

| Cost Analysis of Linear Guideway Block | Pricing factors, Budget considerations, ROI |

| Top Manufacturers of Linear Guideway Block | Hiwin, THK, NSK, SKF |

| Case Studies Using Linear Guideway Block | Aerospace industry, 3D printing technology |

| Linear Guideway Block Standards | ISO, DIN, JIS compliance |

| Environmental Considerations of Linear Guideway Block | Eco-friendly lubrication, Recyclable materials |

| Linear Guideway Block in Modern Automation | Role in Industry 4.0, IoT-enabled systems |

| FAQs about Linear Guideway Block | Covering installation, durability, and selection |

| Conclusion | Final thoughts on importance and future scope |

Introduction to Linear Guideway Block

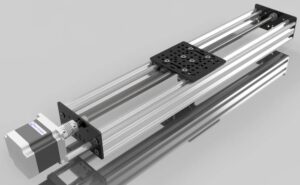

A linear guideway block is a crucial component in precision engineering that ensures smooth, accurate, and stable motion in a straight line. Without it, CNC machines, industrial robots, and even delicate medical equipment would lack the accuracy they demand. Over the years, linear motion technology has evolved from basic sliding mechanisms to advanced rolling guideways that minimize friction while maximizing load capacity.

In fact, industries today rely heavily on linear guideway blocks for tasks that require micrometer-level precision. From semiconductor manufacturing to aerospace assembly, these components make modern engineering possible. Understanding their structure, function, and applications helps engineers, technicians, and manufacturers make better choices for their projects.

Understanding Linear Guideway Block

At its core, a linear guideway block is a motion component that moves along a linear rail to provide accurate straight-line movement. It uses rolling elements—often steel balls or rollers—between the block and the rail. This reduces friction dramatically compared to sliding systems.

The block usually comes in different shapes and sizes, designed to handle varied loads and speeds. Some are built compact for small devices, while others are heavy-duty for massive machinery. The structure typically includes:

Guide block housing (outer casing)

Rolling elements (balls or rollers)

End caps and seals (prevent dust and maintain lubrication)

Preload adjustment system (to control rigidity and play)

Together, these parts ensure reliable, long-lasting motion.

Types of Linear Guideway Blocks

Linear guideway blocks are not one-size-fits-all. Their design varies based on the intended application, load capacity, and space constraints. Engineers usually choose between several main types:

Flanged Type

These have an extended mounting surface with bolt holes, making them easier to secure. They’re perfect when stability is crucial, especially in heavy-duty industrial setups.Square Type

A more compact option that fits into tight spaces without compromising strength. Square types are widely used in CNC machinery where every millimeter of space matters.Slim Type

Designed for applications with space restrictions, such as medical instruments or semiconductor equipment. While smaller, they still maintain high precision.Heavy-Load Type

Built to withstand immense loads, these blocks feature larger rolling elements and reinforced housings. Industries like aerospace and construction machinery benefit most from these.

Choosing the right type directly impacts not only performance but also the lifespan of the entire machine.

Materials Used in Linear Guideway Block

The durability of a linear guideway block largely depends on the materials used. Since these blocks operate in challenging conditions—often under constant movement and load—they must resist wear, corrosion, and deformation. Common materials include:

Stainless Steel – Ideal for environments prone to corrosion, such as food processing or medical applications.

Carbon Steel – Offers a balance between cost-effectiveness and durability. Frequently used in general manufacturing.

Polymer Coatings – Applied to reduce noise, friction, and wear. They also improve resistance against contaminants.

Ceramic Rolling Elements – In high-end blocks, ceramic balls or rollers are used to minimize friction and extend service life.

Material selection directly impacts factors such as speed, precision, and load handling capacity.

Design Features of Linear Guideway Block

One of the reasons a linear guideway block stands out compared to traditional sliding mechanisms is its innovative design. Here are some critical features:

Preload System – This eliminates clearance (play) between the block and the rail, ensuring rigidity. Preload also helps resist vibrations during high-speed machining.

Rolling Elements – Balls or cylindrical rollers carry loads and reduce friction. Roller-based designs handle heavier loads compared to ball-based ones.

Sealing Mechanism – Dust seals, scrapers, and lubricating ports protect the internal rolling elements from contamination, significantly extending life.

Lubrication Channels – Many modern blocks include grease nipples or oil ports for easy maintenance.

These design elements make linear guideway blocks indispensable for machines requiring stability and repeatable precision.

How Linear Guideway Block Works

The working principle of a linear guideway block is deceptively simple but highly efficient. The block slides along a rail, supported by rolling elements that carry the load. Instead of sliding directly on the rail, the balls or rollers move within grooves, drastically reducing contact friction.

Load Distribution – Depending on preload and design, loads are distributed across multiple rolling elements, improving stability.

Friction Reduction – Rolling friction is significantly lower than sliding friction, which means less wear and higher efficiency.

Motion Stability – The controlled rolling action provides smooth movement with minimal deviation, ensuring accurate positioning.

This combination allows machines to achieve both high-speed motion and precise accuracy—a balance that traditional sliding guides struggle to maintain.

Advantages of Linear Guideway Block

There’s a reason industries prefer linear guideway blocks over older systems. Their benefits are unmatched:

High Precision – Essential for tasks like CNC machining or semiconductor manufacturing.

Smooth Motion – Rolling elements ensure a near-frictionless operation.

Long Lifespan – With proper maintenance, they last significantly longer than traditional sliding systems.

Load Capacity – Can handle both radial and axial loads with ease.

Reduced Maintenance Costs – Built-in sealing and lubrication systems reduce downtime.

For manufacturers, these advantages translate into higher productivity, lower operating costs, and consistent output quality.

Common Applications of Linear Guideway Block

Linear guideway blocks are everywhere—even in places where most people don’t notice. Some of the most common applications include:

CNC Machines – Provide stability and accuracy in cutting, milling, and drilling.

Medical Equipment – Used in surgical robots, imaging machines, and lab automation tools.

Robotics – Enable smooth and accurate movements, critical for robotic arms.

Semiconductor Industry – Facilitate ultra-precise wafer processing.

3D Printing – Allow printers to move precisely in X, Y, and Z axes.

Each industry adapts the guideway block type depending on precision, load, and environmental needs.

Linear Guideway Block in CNC Machines

CNC machining is perhaps the biggest beneficiary of linear guideway blocks. In this industry, even a micron of error can mean costly waste. These blocks help CNC machines achieve:

Cutting Accuracy – By eliminating unwanted play or vibration.

Faster Processing – Smooth motion allows for higher speeds without sacrificing precision.

Extended Tool Life – Stable cutting reduces tool wear.

When paired with servo motors and ball screws, linear guideway blocks turn CNC machines into precision workhorses that deliver repeatable accuracy across thousands of cycles.