Outline for Long-form Article on Linear Bearing Rail

| Section | Subtopics |

|---|---|

| Introduction | What is a linear bearing rail? Why it matters |

| Linear Bearing Rail | Definition, role, and key functions |

| Evolution of Linear Bearing Rail Systems | From bushings to advanced rail technology |

| Key Components | Rail, bearing block, rolling elements, seals |

| How Linear Bearing Rails Work | Recirculating elements, load distribution |

| Types of Linear Bearing Rails | Profile rails, round rails, miniature rails |

| Advantages of Linear Bearing Rails | Precision, rigidity, efficiency |

| Challenges and Limitations | Cost, contamination, alignment |

| Applications in CNC Machinery | Milling, grinding, 3D printing |

| Applications in Robotics | Automation, cobots, pick-and-place |

| Applications in Medical Technology | Imaging, surgery, diagnostics |

| Applications in Aerospace and Defense | Assembly, testing, satellite systems |

| Applications in Logistics and Packaging | Conveyors, warehouses, packaging lines |

| Linear Bearing Rails vs Other Motion Systems | Belts, bushings, wheels |

| Choosing the Right Linear Bearing Rail | Load, environment, accuracy, speed |

| Installation Best Practices | Mounting, alignment, torque |

| Maintenance and Care | Lubrication, inspection, cleaning |

| Common Problems and Failures | Misalignment, wear, contamination |

| Future of Linear Bearing Rails | Smart rails, predictive maintenance |

| Sustainability in Linear Motion Systems | Eco-friendly designs, energy efficiency |

| Top Global Manufacturers | THK, HIWIN, Bosch Rexroth |

| Linear Bearing Rails in DIY and Maker Projects | 3D printers, CNC routers |

| Cost Considerations | Factors influencing price |

| Buying Guide | Where and how to buy |

| Linear Bearing Rail | Recap and importance |

| FAQs | Six practical Q&As |

| Conclusion | Final thoughts and outlook |

Introduction

Every modern machine that requires precision, stability, and smooth linear motion depends on a strong backbone: the linear bearing rail. Whether it’s a CNC machine cutting through titanium, a robotic arm assembling electronics, or a medical imaging system scanning patients, linear bearing rails ensure accuracy and repeatability.

They are more than just guiding systems; they represent the perfect balance of load-bearing strength and friction reduction. Without them, automation and advanced manufacturing would struggle to meet today’s exacting standards.

Linear Bearing Rail

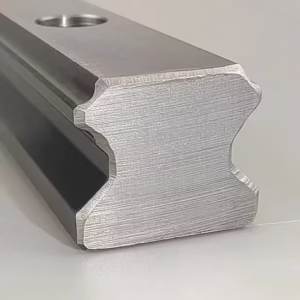

A linear bearing rail is a mechanical system designed to support and guide objects in straight-line motion. It consists of a hardened steel rail paired with a bearing block or carriage that moves along it. Inside the block are rolling elements—typically steel balls or rollers—that minimize friction and provide smooth, precise movement.

These systems are essential in industries where reliability and precision are critical, from small 3D printers to aerospace assembly lines.

Evolution of Linear Bearing Rail Systems

The earliest linear motion relied on sliding bushings. While simple, they generated high friction and wore out quickly. As demand for precision grew, industries transitioned to recirculating ball linear bearings.

Modern linear bearing rails now include:

Profile rails for high rigidity

Round rails for easy installation

Miniature rails for compact devices

Smart rails with integrated sensors

Key Components

Rail – Precision-ground hardened steel track.

Bearing Block/Carriage – The moving part containing rolling elements.

Rolling Elements – Steel balls or rollers that circulate to reduce friction.

Seals and Shields – Protect against dust and debris.

Lubrication System – Provides long-term smooth operation.

How Linear Bearing Rails Work

The principle is simple: rolling elements recirculate inside the block as it moves along the rail. This allows heavy loads to be carried with minimal resistance. The load distribution across multiple contact points ensures rigidity and stability, even at high speeds.

Types of Linear Bearing Rails

Profile Rails

Square, rigid, highly accurate

Used in CNC machining, robotics

Round Rails

Cylindrical, easier to install

Common in logistics and packaging

Miniature Rails

Compact, lightweight

Found in medical and electronics industries

Advantages of Linear Bearing Rails

High precision and repeatability

Long service life

Handles heavy loads with stability

Low friction and reduced noise

Compact and efficient design

Increased speed and productivity

Challenges and Limitations

Higher upfront cost than bushings

Sensitive to dirt and contamination

Require precise installation

Depend on lubrication for smooth operation

Applications in CNC Machinery

CNC machines rely on linear bearing rails for:

Milling and turning

Grinding systems

Laser and water jet cutters

3D printers

They ensure cutting tools move with micron-level precision.

Applications in Robotics

Linear bearing rails are essential in:

Industrial robotic arms

Pick-and-place machines

Collaborative robots (cobots)

They allow robots to perform high-speed, accurate, and repeatable movements.

Applications in Medical Technology

MRI and CT scanners

Robotic surgical systems

Automated laboratory equipment

Miniature linear rails ensure smooth, vibration-free performance in sensitive devices.

Applications in Aerospace and Defense

Aircraft assembly lines

Satellite positioning systems

Flight simulators

These require rigid, vibration-resistant motion systems.

Applications in Logistics and Packaging

Conveyor systems

Automated warehouses

High-speed packaging lines

Smooth rail systems increase efficiency and reliability.

Linear Bearing Rails vs Other Motion Systems

| Feature | Linear Bearing Rail | Belts & Pulleys | Bushings |

|---|---|---|---|

| Precision | Very High | Medium | Low |

| Load Capacity | High | Medium | Low |

| Friction | Very Low | Medium | High |

| Durability | Long | Medium | Short |

| Cost | Higher | Lower | Lowest |

Choosing the Right Linear Bearing Rail

Load requirements

Precision needs

Environmental factors (dust, temperature, moisture)

Budget

Installation Best Practices

Ensure rails are aligned

Use flat, rigid mounting surfaces

Apply correct torque settings

Test for smooth travel before operation

Maintenance and Care

Lubricate periodically

Clean rails regularly

Replace worn seals

Inspect for misalignment

Common Problems and Failures

Misalignment causing uneven wear

Lack of lubrication increasing friction

Contaminants damaging rolling elements

Overloading rails beyond design limits

Future of Linear Bearing Rails

Smart rails with IoT sensors

Self-lubricating materials

AI-based predictive maintenance

Lightweight composites for efficiency

Sustainability in Linear Motion Systems

Use of recyclable materials

Energy-efficient manufacturing

Longer lifespan reducing waste

Top Global Manufacturers

THK – Japan

HIWIN – Taiwan

Bosch Rexroth – Germany

NSK Motion Solutions – Japan

SKF – Sweden

Linear Bearing Rails in DIY and Maker Projects

CNC routers

3D printers

Laser cutters

Affordable linear rail kits allow hobbyists to build professional-quality machines.

Cost Considerations

Price depends on:

Rail type (profile vs round)

Bearing design (ball vs roller)

Precision grade

Brand reputation

Buying Guide

Best sources include:

Manufacturer websites

Industrial suppliers like RS Components and McMaster-Carr

Online engineering marketplaces

Linear Bearing Rail

In summary, the linear bearing rail is the heart of modern precision motion. From CNC machines to robotics and aerospace, it provides the stability and accuracy industries demand.

FAQs

What is a linear bearing rail used for?

It enables precise straight-line motion in machines and automation systems.

Which is better: profile or round rails?

Profile rails are more rigid and precise, while round rails are easier to install.

Do linear bearing rails need lubrication?

Yes, lubrication prevents wear and extends lifespan.

Can linear bearing rails handle heavy loads?

Yes, especially roller-type rails designed for high loads.

Are linear bearing rails expensive?

They cost more than bushings but are more durable and efficient.

Can they be used outdoors?

Yes, but they need protective seals and corrosion-resistant coatings.

Conclusion

The linear bearing rail may seem like a small component, but its impact is enormous. It enables industries to achieve speed, precision, and reliability. From medical robotics to aerospace engineering, its role is unmatched.

With advances in smart sensors and eco-friendly designs, the future of linear bearing rails promises even greater efficiency and sustainability.