Outline for Long-form Article on Linear Slide Rail

| Section | Subtopics |

|---|---|

| Introduction | What is a linear slide rail? Why it matters |

| Linear Slide Rail | Core definition and role in precision systems |

| History and Evolution of Slide Rails | From plain sliders to advanced rail systems |

| Key Components of a Linear Slide Rail | Rails, blocks, rolling elements, seals |

| How Linear Slide Rails Work | Recirculating elements, load transfer |

| Types of Linear Slide Rails | Profile rails, round rails, miniature rails |

| Advantages of Linear Slide Rails | Accuracy, rigidity, efficiency |

| Drawbacks and Limitations | Cost, contamination, installation |

| Applications in CNC Machines | Milling, turning, laser cutting |

| Applications in Robotics | Automation arms, cobots, pick-and-place |

| Applications in Medical Systems | Imaging, diagnostics, surgery tools |

| Applications in Aerospace and Defense | Assembly, testing, simulators |

| Applications in Packaging and Logistics | Conveyors, automated warehouses |

| Linear Slide Rail vs Other Motion Systems | Belts, bushings, wheels |

| Choosing the Right Linear Slide Rail | Load, environment, precision needs |

| Installation Best Practices | Alignment, torque, flatness |

| Maintenance of Linear Slide Rails | Lubrication, inspection, cleaning |

| Common Problems and Failures | Misalignment, wear, contamination |

| Future of Linear Slide Rail Technology | Smart sensors, predictive maintenance |

| Eco-friendly and Sustainable Rail Systems | Green materials, longer service life |

| Top Global Manufacturers | THK, HIWIN, Bosch Rexroth |

| Linear Slide Rails in DIY and Maker Projects | CNC routers, 3D printers |

| Cost Considerations | Factors influencing price |

| Buying Guide for Linear Slide Rails | Where to buy, quality checks |

| Linear Slide Rail | Recap and final insights |

| FAQs | Six practical questions and answers |

| Conclusion | Final thoughts and outlook |

Introduction

Imagine a CNC machine cutting through steel with micrometer precision or a robotic arm assembling electronics flawlessly. None of this would be possible without linear slide rails. These essential components provide the foundation for smooth, accurate, and repeatable motion in countless machines and devices.

In today’s world of high-speed automation and precision engineering, the linear slide rail has become a backbone of industries ranging from medical devices to aerospace. By reducing friction and supporting heavy loads, it allows modern machines to work faster, smarter, and longer.

Linear Slide Rail

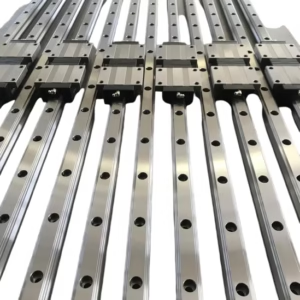

A linear slide rail is a guiding system that allows one component to move in a straight line relative to another with minimal friction. It consists of a hardened steel rail and a sliding block or carriage that houses rolling elements like steel balls or rollers.

The main goal of a linear slide rail is to provide accurate and stable linear motion while supporting loads in multiple directions. Whether in a simple 3D printer or a complex aircraft assembly line, these systems ensure precision.

History and Evolution of Slide Rails

The earliest linear motion systems were simple plain slides or bushings, which worked but generated excessive friction and required constant lubrication. As industries demanded higher precision, engineers developed recirculating ball slide rails, transforming manufacturing in the late 20th century.

Today, we see advanced profile slide rails, miniature rails, and even smart slide rails equipped with sensors for predictive maintenance.

Key Components of a Linear Slide Rail

Rail: Precision-ground steel track.

Carriage/Block: Moves along the rail and holds rolling elements.

Rolling Elements: Steel balls or rollers that reduce friction.

Seals: Protect against dust and contaminants.

Lubrication System: Ensures smooth, long-lasting operation.

How Linear Slide Rails Work

The working principle is based on recirculating rolling elements. Steel balls or rollers inside the carriage circulate as the block moves along the rail. This rolling action minimizes resistance and distributes loads evenly.

The result? Smooth, accurate, and stable linear motion capable of handling both light and heavy-duty applications.

Types of Linear Slide Rails

Profile Rails: Square-edged, rigid, highly precise; ideal for CNC and aerospace.

Round Rails: Cylindrical shape, easier installation, more forgiving of misalignment.

Miniature Rails: Compact, lightweight, ultra-precise; used in medical and electronics.

Advantages of Linear Slide Rails

High precision and repeatability

Long service life with proper care

Ability to handle heavy loads

Reduced friction and noise

Compact and space-saving design

Increased machine speed and efficiency

Drawbacks and Limitations

Higher initial cost compared to bushings

Sensitive to dust, dirt, and moisture

Require careful alignment during installation

Dependence on lubrication for smooth operation

Applications in CNC Machines

CNC systems demand accuracy at high speeds. Linear slide rails are used in:

Milling machines

Grinding systems

Laser cutters

3D printers

They ensure the cutting tool or platform moves with stability.

Applications in Robotics

Robotic systems rely on linear slide rails for:

Robotic arms and manipulators

Automated pick-and-place systems

Collaborative robots (cobots)

These rails help robots perform precise, repeatable movements thousands of times per hour.

Applications in Medical Systems

The medical field requires high-accuracy tools powered by linear slide rails, including:

MRI and CT scanners

Surgical robotics

Laboratory automation

Miniature slide rails ensure smooth operation in delicate medical devices.

Applications in Aerospace and Defense

Aircraft assembly stations

Satellite deployment mechanisms

Flight simulators

Slide rails ensure rigidity, vibration resistance, and stability.

Applications in Packaging and Logistics

In high-speed packaging and warehouses, linear slide rails power:

Conveyor systems

Automated sorting and labeling machines

Pickers and palletizers

Linear Slide Rail vs Other Motion Systems

| Feature | Linear Slide Rail | Belts & Pulleys | Bushings |

|---|---|---|---|

| Precision | Very High | Medium | Low |

| Load Capacity | High | Medium | Low |

| Friction | Very Low | Medium | High |

| Durability | Long | Medium | Low |

| Cost | Higher | Lower | Lowest |

Choosing the Right Linear Slide Rail

Consider these factors:

Load requirements

Speed of operation

Precision needs

Environmental conditions

Budget

Installation Best Practices

Ensure rail alignment

Use flat, clean surfaces

Apply recommended torque levels

Test movement before full load operation

Maintenance of Linear Slide Rails

Lubricate regularly

Clean and protect against dust

Replace seals if worn

Monitor for unusual vibration or noise

Common Problems and Failures

Misalignment causing uneven wear

Lack of lubrication leading to friction

Contamination reducing smoothness

Overloading damaging the rails

Future of Linear Slide Rail Technology

Smart rails with sensors for predictive maintenance

Self-lubricating designs for reduced upkeep

Lightweight composite materials for efficiency

AI-driven monitoring to predict wear and failure

Eco-friendly and Sustainable Rail Systems

Longer lifespan reduces waste

Energy-efficient motion systems

Use of recyclable materials in production

Top Global Manufacturers

THK (Japan)

HIWIN (Taiwan)

Bosch Rexroth (Germany)

NSK Motion Solutions (Japan)

SKF (Sweden)

Linear Slide Rails in DIY and Maker Projects

Makers and hobbyists use slide rails in:

3D printers

Laser engravers

These systems make affordable precision engineering accessible to everyone.

Cost Considerations

Price depends on:

Rail type (profile vs round)

Bearing design (ball vs roller)

Precision grade

Manufacturer reputation

Buying Guide for Linear Slide Rails

Best options include:

Manufacturer-direct orders

Industrial suppliers like McMaster-Carr

Online marketplaces for hobbyist kits

Linear Slide Rail

In essence, the linear slide rail is the foundation of precision motion in countless industries. From medical tools to aerospace engineering, it ensures reliability, accuracy, and efficiency.

FAQs

What is a linear slide rail used for?

It guides precise, smooth, straight-line motion in machines.

Do linear slide rails need lubrication?

Yes, lubrication reduces wear and ensures smooth operation.

Which is better: profile rails or round rails?

Profile rails are more precise, while round rails are easier to install.

Can linear slide rails handle heavy loads?

Yes, especially profile rails with roller bearings.

Are linear slide rails expensive?

They are costlier than bushings but offer long-term savings.

Can they be used in outdoor environments?

Yes, with protective coatings and seals.

Conclusion

The linear slide rail is a small component with a huge impact. It powers industries by providing the precision and reliability that modern automation demands. From CNC machines to medical equipment, slide rails continue to shape the future of technology.

As innovations like smart sensors and self-lubricating materials emerge, the role of linear slide rails will only grow. Whether in a factory, a lab, or a DIY workshop, they remain essential for smooth, accurate, and efficient motion.