Introduction

As manufacturing, automation, and precision engineering continue to evolve, the demand for accurate, stable, and repeatable linear motion has never been higher. At the heart of this motion lies one of the most essential mechanical components used across industries: linear guide rail systems.

Linear guide rail systems are designed to guide moving machine parts along a straight path while supporting loads and minimizing friction. From CNC machining centers and industrial robots to packaging machines, medical equipment, and semiconductor production, these systems play a vital role in ensuring precision, efficiency, and reliability.

This article provides a comprehensive overview of linear guide rail systems, covering their structure, working principles, types, materials, advantages, applications, selection criteria, and maintenance best practices.

What Are Linear Guide Rail Systems?

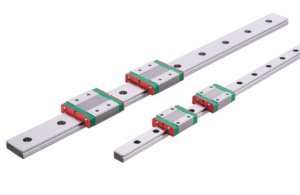

A linear guide rail system is a mechanical assembly that allows components to move linearly with high accuracy and low friction. It typically consists of:

Linear guide rails (fixed tracks)

Bearing carriages or blocks (moving elements)

Rolling elements (balls or rollers inside the carriage)

Unlike traditional sliding mechanisms, linear guide rail systems rely on rolling contact, which significantly reduces friction, wear, and energy loss. This design enables smooth motion, high load capacity, and long service life.

Core Components of a Linear Guide Rail System

1. Linear Guide Rail

The rail is a precision-machined track mounted to the machine frame. It provides a rigid reference surface that ensures straight and stable motion. Rails are typically heat-treated for wear resistance and dimensional stability.

2. Bearing Carriage (Slider or Block)

The carriage moves along the rail and supports the applied load. It houses the rolling elements and is designed to maintain alignment while handling forces from multiple directions.

3. Rolling Elements

Rolling elements reduce friction and allow smooth movement. Depending on the system design, these can be:

Steel balls for speed and precision

Cylindrical rollers for higher load capacity and rigidity

4. Seals, Wipers, and Lubrication Ports

These components protect the internal bearing system from contamination and ensure consistent lubrication, which is critical for long-term performance.

How Linear Guide Rail Systems Work

Linear guide rail systems operate using the principle of recirculating rolling motion:

The carriage moves along the rail under load.

Rolling elements circulate within internal tracks inside the carriage.

Rolling contact replaces sliding friction, reducing resistance.

The system maintains accurate alignment even under dynamic loads.

This mechanism allows linear guide rail systems to support radial, axial, and moment loads simultaneously, making them suitable for complex and demanding applications.

Types of Linear Guide Rail Systems

1. Ball-Type Linear Guide Rail Systems

Use recirculating steel balls

Low friction and high precision

Ideal for CNC machines, 3D printers, and automation equipment

2. Roller-Type Linear Guide Rail Systems

Use cylindrical or needle rollers

Higher rigidity and load capacity

Suitable for heavy-duty machinery and large industrial systems

3. Profiled Linear Guide Rail Systems

Compact rail and block design

Supports multi-directional loads

Common in robotics and high-speed automation

4. Miniature Linear Guide Rail Systems

Small size and lightweight

Designed for limited spaces

Used in medical devices, electronics, and laboratory equipment

5. Aluminum Linear Guide Rail Systems

Lightweight and corrosion-resistant

Often anodized

Popular in robotics, 3D printing, and portable machinery

6. Round Rail Linear Guide Systems

Cylindrical rails with linear bushings

Cost-effective solution

Best for light loads and low-speed applications

Key Advantages of Linear Guide Rail Systems

High Precision and Repeatability

Linear guide rail systems maintain tight tolerances, making them ideal for precision machining and automated processes.

Low Friction and Smooth Motion

Rolling contact reduces friction, leading to quieter operation and improved energy efficiency.

High Load Capacity

Advanced designs allow systems to support combined loads from multiple directions.

Long Service Life

Reduced wear and proper lubrication contribute to extended operational life.

Excellent Rigidity

High stiffness minimizes deflection, improving machining accuracy.

Versatility

Compatible with a wide range of industrial applications and environments.

Applications of Linear Guide Rail Systems

Linear guide rail systems are widely used across multiple industries:

CNC machining centers

Industrial robots and automation systems

Packaging and labeling machines

Semiconductor manufacturing equipment

Medical and laboratory automation

Laser cutting and engraving machines

Material handling systems

Textile and printing machinery

Their adaptability and performance make them indispensable in modern manufacturing.

Materials Used in Linear Guide Rail Systems

Hardened Carbon Steel

High strength and wear resistance

Most common material for industrial use

Stainless Steel

Corrosion-resistant

Ideal for food, medical, and cleanroom environments

Aluminum Alloys

Lightweight and corrosion-resistant

Used where weight reduction is critical

Special Coatings

Anti-corrosion, low-friction, or wear-resistant coatings

Improve performance in harsh environments

How to Choose the Right Linear Guide Rail System

Selecting the correct system depends on several factors:

Load Requirements – Consider static, dynamic, and moment loads

Precision Level – Match rail accuracy grade to application needs

Speed and Acceleration – Ensure compatibility with motion requirements

Environmental Conditions – Dust, moisture, and chemicals affect material choice

Installation Space – Compact systems for tight layouts

Maintenance Needs – Ease of lubrication and sealing options

Cost vs. Performance – Balance budget and long-term reliability

Installation Best Practices

Ensure mounting surfaces are flat and rigid

Align rails precisely to prevent binding

Use recommended torque values for fasteners

Apply proper lubrication before operation

Follow manufacturer installation guidelines closely

Correct installation is essential to achieving the system’s rated accuracy and lifespan.

Maintenance and Service Guidelines

Regular maintenance ensures optimal performance:

Inspect rails and carriages for wear or contamination

Clean surfaces to prevent debris buildup

Re-lubricate according to operating conditions

Monitor noise or vibration as early warning signs

Replace worn components promptly

Preventive maintenance significantly extends system life and reduces downtime.

Future Trends in Linear Guide Rail Systems

The linear motion industry continues to evolve with innovations such as:

Smart linear guides with integrated sensors

IoT-based condition monitoring

Advanced low-friction coatings

Lightweight hybrid material designs

Maintenance-free and self-lubricating systems

These advancements support the growth of Industry 4.0 and smart manufacturing.

Frequently Asked Questions (FAQs)

What is a linear guide rail system used for?

It provides precise, low-friction linear motion for machines and automation equipment.

What is the difference between ball and roller guide rails?

Ball guides offer higher speed and precision, while roller guides provide greater load capacity and rigidity.

How long do linear guide rail systems last?

With proper installation and maintenance, they can operate reliably for many years.

Can linear guide rail systems handle heavy loads?

Yes, especially roller-type and high-rigidity profile rail systems.

Do linear guide rails require lubrication?

Yes, lubrication is essential to reduce wear and maintain smooth operation.

Conclusion

Linear guide rail systems are a cornerstone of modern precision machinery. Their ability to provide smooth, accurate, and reliable linear motion makes them indispensable in CNC machining, robotics, automation, and advanced manufacturing.

By understanding system types, materials, installation practices, and maintenance requirements, engineers and manufacturers can select the optimal linear guide rail system for their specific application. As technology advances, these systems will continue to evolve, supporting higher precision, greater efficiency, and smarter manufacturing solutions.