Outline for “Linear Slide Bearing”

| Section | Sub-Sections |

|---|---|

| Introduction | Why linear motion technology matters |

| Linear Slide Bearing | Definition and function |

| Evolution of Linear Slide Bearing | From early slides to precision systems |

| Components of a Linear Slide Bearing | Housing, bearing, rolling/sliding surface |

| Types of Linear Slide Bearings | Ball, roller, plain, self-lubricating |

| Ball-Type Linear Slide Bearings | High precision and speed |

| Roller-Type Linear Slide Bearings | Heavy-duty performance |

| Plain Linear Slide Bearings | Durability and contamination resistance |

| Self-Lubricating Linear Bearings | Maintenance-free designs |

| Materials in Linear Slide Bearings | Steel, polymers, ceramics, aluminum |

| Benefits of Linear Slide Bearing Systems | Accuracy, long life, low friction |

| Industrial Applications | CNC, packaging, assembly lines |

| Use in Robotics and Automation | Robotic arms, conveyors, pick-and-place |

| Medical Applications | Imaging devices, surgical robotics |

| Aerospace and Defense Uses | Aircraft assembly, testing simulators |

| Consumer and DIY Applications | 3D printers, furniture, camera sliders |

| Installation Tips | Alignment, preload, lubrication |

| Maintenance Best Practices | Cleaning, lubrication, inspection |

| Choosing the Right Linear Slide Bearing | Load, speed, operating environment |

| Comparison with Linear Guides and Rails | Pros and cons |

| Latest Innovations | IoT-enabled, lightweight composites |

| Cost Considerations | Budget vs premium solutions |

| Common Problems and Fixes | Noise, wear, binding |

| Best Manufacturers Worldwide | THK, Hiwin, SKF, Bosch Rexroth |

| Future of Linear Slide Bearings | Smart factories and AI-driven maintenance |

| FAQs | Expert answers |

| Conclusion | Final thoughts |

Introduction

Modern industry thrives on precision, and at the heart of this precision lies linear slide bearings. These mechanical components enable smooth and controlled motion in a straight line, eliminating unnecessary friction and ensuring stability. From heavy-duty CNC machines to delicate medical equipment, linear slide bearings keep the world moving with accuracy and efficiency.

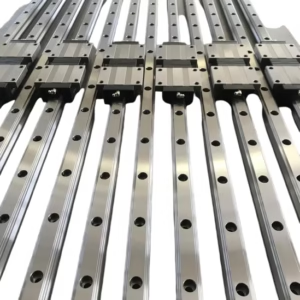

Linear Slide Bearing

A linear slide bearing is a device that supports and guides motion along a straight path with minimal friction. It typically works in conjunction with a rail or shaft, where the bearing either slides or rolls to facilitate smooth linear movement.

In simpler terms, imagine a drawer gliding open and closed effortlessly—that’s a basic form of a slide bearing at work.

Evolution of Linear Slide Bearing

Early Systems: Wooden grooves and metal slides guided simple machinery.

Industrial Era: Steel and brass bearings increased strength and durability.

Modern Advances: Today’s slide bearings feature high-precision machining, advanced materials, and even IoT-enabled designs for predictive maintenance.

Components of a Linear Slide Bearing

Housing/Body: The external structure that holds the bearing.

Bearing Element: Balls, rollers, or plain sliding surfaces.

Shaft or Rail: The guide path for movement.

Seals and End Caps: Protect against dust and contaminants.

Types of Linear Slide Bearings

Ball-Type Linear Slide Bearings

Equipped with circulating ball bearings that reduce friction and allow high-speed, precise movement. Common in CNC machines and automation equipment.

Roller-Type Linear Slide Bearings

Use cylindrical rollers instead of balls, spreading loads more evenly. Ideal for heavy-duty applications requiring rigidity.

Plain Linear Slide Bearings

Also called bushings, these rely on direct sliding surfaces. They are resistant to dust and debris, making them suitable for rugged environments.

Self-Lubricating Bearings

Designed with special materials or coatings that eliminate the need for regular lubrication, reducing maintenance efforts.

Materials in Linear Slide Bearings

Stainless Steel: Corrosion-resistant, durable, ideal for clean industries.

Carbon Steel: Strong and affordable, used in general industry.

Polymers: Lightweight, corrosion-resistant, low-maintenance.

Ceramics: Heat-resistant and non-magnetic for specialized uses.

Aluminum: Lightweight, often used in housings.

Benefits of Linear Slide Bearing Systems

High accuracy in motion control

Reduced friction for energy efficiency

Long service life with proper care

Wide range of load-bearing capabilities

Quiet and smooth operation

Adaptability across industries

Industrial Applications

Linear slide bearings are widely used in:

CNC machining centers

Packaging and labeling machines

Automated assembly lines

Textile machinery

Use in Robotics and Automation

Robots require precision for repetitive tasks. Linear slide bearings provide smooth movement for robotic arms, conveyor systems, and pick-and-place robots.

Medical Applications

Linear slide bearings play a vital role in:

Imaging devices (MRI, CT scanners)

Laboratory automation machines

Surgical robotics for delicate operations

Aerospace and Defense Uses

Aircraft assembly systems

Flight simulators

Defense-grade automated testing equipment

Consumer and DIY Applications

3D printers for precise layer placement

Camera sliders for filmmaking

Furniture mechanisms like sliding drawers

Installation Tips

Align bearings precisely to avoid binding.

Apply the correct preload for stability.

Use high-quality lubrication for longevity.

Securely mount rails and housings.

Maintenance Best Practices

Clean regularly to remove debris.

Re-lubricate at recommended intervals.

Inspect for wear, noise, or cracks.

Replace faulty parts promptly.

Choosing the Right Linear Slide Bearing

Key factors include:

Load requirements

Expected speed and acceleration

Environmental conditions (dust, humidity, temperature)

Desired precision level

Comparison with Linear Guides and Rails

Linear Guides: Offer higher rigidity but cost more.

Slide Bearings: More affordable, versatile, and simpler to install.

Rails with Bearings: Best for heavy-duty precision applications.

Latest Innovations

IoT-enabled Bearings: Real-time monitoring and predictive maintenance.

Self-Lubricating Designs: Lower maintenance needs.

Noise-Reduction Bearings: Ideal for medical and office environments.

Lightweight Materials: Improve efficiency in automation.

Cost Considerations

Entry-level bearings are affordable for light applications.

High-precision bearings cost more but provide longer service life and higher efficiency.

Common Problems and Fixes

Noise: Often due to insufficient lubrication.

Binding: Misalignment or dirt buildup.

Uneven Wear: Incorrect preload or load distribution.

Best Manufacturers Worldwide

THK – Japanese precision motion systems

Hiwin – Affordable, high-quality bearings

SKF – Global leader in bearing technology

Bosch Rexroth – Heavy-duty industrial solutions

Future of Linear Slide Bearings

With the rise of Industry 4.0, linear slide bearings will become smarter and more connected. Expect AI-driven maintenance alerts, lighter composite materials, and energy-efficient designs shaping the future of precision motion.

FAQs

What is a linear slide bearing used for?

It enables smooth and precise straight-line motion in machines and devices.

Do linear slide bearings need lubrication?

Yes, unless they are self-lubricating, regular lubrication is essential.

Can they handle heavy loads?

Roller-type slide bearings are designed for high load capacities.

Where are linear slide bearings used?

In CNC machines, robotics, aerospace, medical devices, and even consumer electronics.

How long do linear slide bearings last?

With proper care, they can last several years, depending on usage.

Are they expensive?

Basic models are affordable, but high-precision industrial ones are more costly.

Conclusion

The linear slide bearing is a crucial component in modern machinery, offering precision, stability, and durability across countless applications. From heavy industry to consumer gadgets, its role is indispensable. By choosing the right type, installing correctly, and maintaining it well, businesses and individuals can enjoy efficient and reliable performance.

Inbound Link Suggestions

Link to: Guide to CNC Machines

Link to: Robotics in Industry

Link to: Understanding Bearings