Outline for “Linear Bearing Rail”

| Section | Sub-Sections |

|---|---|

| Introduction | Why linear motion systems matter |

| Linear Bearing Rail | Definition and purpose |

| Evolution of Linear Bearing Rail | From early guides to precision rails |

| Anatomy of a Linear Bearing Rail | Rail, carriage, rolling elements |

| Types of Linear Bearing Rails | Profiled, round, miniature, heavy-duty |

| Ball-Type Linear Bearing Rail | Low-friction, high-speed applications |

| Roller-Type Linear Bearing Rail | High load and rigidity |

| Plain Bearing Rail | Rugged, low-maintenance design |

| Key Materials in Linear Bearing Rails | Steel, aluminum, ceramics, polymers |

| Core Benefits of Linear Bearing Rails | Accuracy, durability, low friction |

| Industrial Applications | CNC, packaging, assembly lines |

| Role in Robotics and Automation | Precision arms, pick-and-place robots |

| Medical and Healthcare Uses | Imaging machines, lab automation |

| Aerospace and Defense Applications | Aircraft assembly, simulators |

| Everyday Uses | 3D printers, camera sliders, furniture |

| Installation Guidelines | Preload, lubrication, alignment |

| Maintenance Essentials | Cleaning, lubrication, inspection |

| Choosing the Right Linear Bearing Rail | Load, speed, environment |

| Linear Bearing Rail vs Other Motion Systems | Bushings, plain guides, slides |

| Latest Innovations | IoT sensors, self-lubricating rails |

| Cost Factors | Budget vs premium rails |

| Common Issues and Fixes | Noise, wear, misalignment |

| Leading Global Manufacturers | THK, Hiwin, Bosch Rexroth, SKF |

| Future Trends | Smart factories, AI-driven systems |

| FAQs | Expert answers |

| Conclusion | Key takeaways |

Introduction

Precision is the heartbeat of modern industry. From robots on assembly lines to delicate surgical instruments, achieving smooth and accurate movement is essential. At the center of this motion lies the linear bearing rail—a system designed to deliver frictionless, precise, and reliable linear movement.

Whether in heavy manufacturing or compact consumer devices, linear bearing rails ensure operations remain smooth and efficient. This article explores their construction, benefits, applications, and future trends.

Linear Bearing Rail

A linear bearing rail is a mechanical guide that allows smooth and controlled straight-line motion. It combines a rail with a bearing carriage, enabling loads to move with minimal resistance.

Think of it like a train on a track—without rails, the train would wander aimlessly. Similarly, machines rely on linear bearing rails for stability and precision.

Evolution of Linear Bearing Rail

Early Machines: Wooden slides and simple grooves provided primitive guidance.

Industrial Revolution: Steel rails and bearings increased speed and load capacity.

Modern Era: Today’s rails are equipped with precision-ground steel, rolling elements, and IoT-enabled features for predictive maintenance.

Anatomy of a Linear Bearing Rail

Rail: The fixed guide track.

Carriage/Block: The sliding part that moves along the rail.

Rolling Elements: Balls or rollers that reduce friction.

End Caps/Seals: Protect against dust and contaminants.

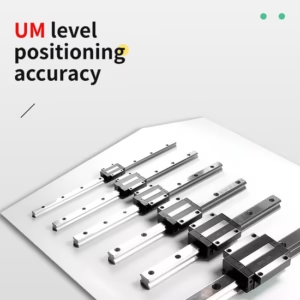

Types of Linear Bearing Rails

Profiled Rails

Rigid and accurate, used in CNC machines and industrial automation.

Round Rails

Cylindrical, easy to install, but less rigid. Ideal for lighter applications.

Miniature Rails

Compact designs for 3D printers, lab equipment, and electronics.

Heavy-Duty Rails

Engineered for high loads and harsh environments.

Ball-Type Linear Bearing Rail

Ball bearings circulate inside the carriage, ensuring low friction and high precision. They are perfect for fast-moving and high-accuracy machines.

Roller-Type Linear Bearing Rail

Instead of balls, cylindrical rollers distribute load across a larger area, providing rigidity and high load capacity. Best suited for heavy machinery.

Plain Bearing Rail

These rely on sliding instead of rolling motion. While not as smooth, they resist contamination and require less maintenance, making them suitable for dusty environments.

Key Materials in Linear Bearing Rails

Stainless Steel: Corrosion resistance for medical and food industries.

Carbon Steel: Strong and affordable for general use.

Aluminum: Lightweight and corrosion-resistant.

Ceramics: Heat-resistant and non-magnetic for specialized sectors.

Polymers: Low-cost and self-lubricating for light-duty tasks.

Core Benefits of Linear Bearing Rails

Smooth, precise linear motion

High load capacity and rigidity

Long service life with minimal wear

Compatibility with automation and robotics

Low friction, noise, and vibration

Industrial Applications

Factories rely on linear bearing rails in:

CNC machining

Packaging and labeling systems

Injection molding

Printing and engraving

Role in Robotics and Automation

Linear bearing rails enable robotic arms to move smoothly and repeatedly, ensuring safety and efficiency in automated production.

Medical and Healthcare Uses

Used in MRI scanners, surgical robots, and diagnostic machines, where accuracy is life-critical.

Aerospace and Defense Applications

From aircraft assembly to high-precision simulators, linear bearing rails ensure stability in demanding environments.

Everyday Uses

3D printers

Camera sliders for film production

Furniture like sliding drawers

Installation Guidelines

Align rails precisely to prevent binding.

Set preload properly to balance stability and friction.

Use lubrication to reduce wear.

Secure mounting bolts tightly.

Maintenance Essentials

Clean regularly to remove dust and debris.

Re-lubricate periodically.

Inspect for cracks, noise, or uneven motion.

Replace worn-out bearings before failure.

Choosing the Right Linear Bearing Rail

Key considerations:

Expected load and speed

Environmental conditions

Precision requirements

Maintenance needs

Linear Bearing Rail vs Other Motion Systems

Bushings: Cheaper but less precise.

Plain Guides: Durable in harsh environments but less smooth.

Bearing Rails: Offer the best balance of precision, speed, and load handling.

Latest Innovations

IoT Sensors: Rails with monitoring systems for predictive maintenance.

Self-Lubricating Designs: Reduce the need for constant upkeep.

Lightweight Composites: Improve energy efficiency.

Noise Reduction Technology: Quieter operation for medical and consumer uses.

Cost Factors

Standard rails are affordable for light use.

Precision industrial rails cost more but last longer and improve productivity.

Common Issues and Fixes

Noise: Often from poor lubrication.

Vibration: Usually due to misalignment.

Uneven Wear: Can result from improper preload or dirt buildup.

Leading Global Manufacturers

THK – Renowned for precision rails

Hiwin – Affordable and widely used

Bosch Rexroth – Industrial-grade heavy-duty rails

SKF – Trusted global brand for bearings and rails

Future Trends

The future points to smart factories using IoT-enabled linear bearing rails that self-monitor, reduce downtime, and optimize machine performance. AI-driven predictive maintenance will further revolutionize how rails are used.

FAQs

What is a linear bearing rail used for?

It provides smooth, friction-free linear motion in machines and equipment.

How long do linear bearing rails last?

With maintenance, they can last many years depending on load and usage.

Do they need lubrication?

Yes, regular lubrication ensures smooth performance and longevity.

Can linear bearing rails be cut to size?

Yes, most can be customized to fit specific applications.

Which industries use them the most?

Manufacturing, robotics, aerospace, medical, and consumer electronics.

Are linear bearing rails expensive?

Basic models are affordable, but precision industrial types can be costly.

Conclusion

The linear bearing rail is more than just a machine component—it is the backbone of precision motion. From heavy industries to everyday devices, it guarantees accuracy, stability, and reliability. Choosing the right rail and maintaining it well ensures smooth performance, longer service life, and cost savings.

Inbound Link Suggestions

Link to: Guide to CNC Machines

Link to: Understanding Bearings

Link to: Robotics in Industry