Comprehensive Outline

| Main Topics | Detailed Coverage |

|---|---|

| Linear Slide Rail Bearings Overview | Definition and industrial role |

| Evolution of Linear Bearing Technology | From plain bearings to rolling systems |

| Linear Slide Rail Bearings Fundamentals | Motion principles |

| Key Components | Rail, bearing block, rolling elements |

| Bearing Materials | Steel grades and durability |

| Surface Treatment and Coatings | Corrosion and wear resistance |

| Load Capacity and Moment Loads | Static and dynamic forces |

| Precision and Smoothness | Accuracy and repeatability |

| Types of Linear Slide Rail Bearings | Ball, roller, miniature |

| Linear Slide Rail Bearings vs Plain Slides | Performance comparison |

| Installation Requirements | Mounting and preparation |

| Alignment and Preload Control | Rigidity optimization |

| Lubrication Systems | Grease and oil options |

| Maintenance and Service Life | Long-term performance |

| Noise and Vibration Control | Motion stability |

| Automation Applications | Robotics and assembly lines |

| CNC and Machine Tools | Cutting accuracy support |

| Medical and Laboratory Equipment | Clean and precise motion |

| Electronics and Semiconductor Use | Cleanroom compatibility |

| Heavy Industry Applications | High-load machinery |

| Selecting the Right Bearings | Technical considerations |

| Common Selection Mistakes | Oversizing and misalignment |

| Cost Efficiency and ROI | Long-term value |

| YH Linear Linear Slide Rail Bearings | Brand expertise |

| Future Trends | Smart and sensor-integrated bearings |

Introduction

In modern machinery, motion quality often defines overall performance. Linear slide rail bearings play a vital role in ensuring smooth, accurate, and reliable linear movement across countless industrial applications. From automation systems to CNC machine tools, these components quietly support precision and productivity every day.

At YH Linear, years of experience in linear motion technology have shown that choosing the right linear slide rail bearings can significantly reduce friction, improve accuracy, and extend machine service life. This article explores how linear slide rail bearings work, why they matter, and how YH Linear delivers dependable solutions for demanding industries.

Linear Slide Rail Bearings

Linear slide rail bearings are mechanical systems designed to guide moving components along a straight path using rolling elements such as balls or rollers. Unlike plain sliding bearings, which rely on surface contact, linear slide rail bearings reduce friction by replacing sliding motion with rolling motion.

This design allows for higher speeds, improved accuracy, and consistent performance over long operating cycles. Linear slide rail bearings also support loads from multiple directions, making them ideal for complex mechanical systems.

At YH Linear, linear slide rail bearings are engineered to deliver stable motion even under harsh industrial conditions, ensuring confidence in every movement.

Evolution of Linear Bearing Technology

Early machines relied on plain slides and bushings. While simple, these systems generated high friction and required frequent maintenance. Over time, engineers sought more efficient solutions.

The development of rolling-element technology transformed linear motion. By introducing balls and rollers into bearing systems, linear slide rail bearings dramatically improved efficiency and durability.

Today, advanced manufacturing techniques allow for micron-level tolerances, making modern linear slide rail bearings essential for precision engineering.

Engineering Principles Behind Linear Slide Rail Bearings

The primary principle behind linear slide rail bearings is rolling contact. Balls or rollers circulate within the bearing block, distributing load evenly along the rail.

Preload is another critical concept. By applying internal pressure, linear slide rail bearings eliminate clearance, increasing rigidity and positioning accuracy.

Load distribution ensures that forces are absorbed from multiple directions. This balanced design allows machines to operate smoothly even under dynamic loads.

Key Components of Linear Slide Rail Bearings

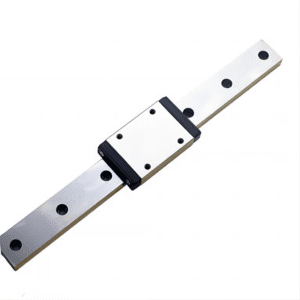

A typical linear slide rail bearing system consists of a precision-ground rail, a bearing block, rolling elements, seals, and lubrication channels.

The rail provides the guiding surface, while the bearing block houses the rolling elements. Balls or rollers move smoothly along hardened raceways, reducing friction.

Seals protect against dust and debris, while lubrication ports ensure long-term smooth operation. YH Linear carefully controls each component to maintain consistent quality.

Materials and Surface Treatments

High-quality materials are essential for reliable linear slide rail bearings. Hardened alloy steel is commonly used for its strength and wear resistance.

Surface treatments such as black oxide or special coatings enhance corrosion resistance. These features are especially important in humid or chemically aggressive environments.

YH Linear offers customized material and coating options to match specific application requirements.

Load Capacity and Moment Handling

Linear slide rail bearings are designed to handle complex load conditions. They support vertical loads, lateral forces, and moment loads simultaneously.

Roller-type linear slide rail bearings provide higher rigidity for heavy-duty applications. Ball-type systems offer excellent speed and smoothness for lighter loads.

Correct load calculation ensures optimal bearing selection. YH Linear provides technical guidance to help customers avoid oversizing or underperformance.

Precision, Accuracy, and Smooth Motion

Precision is one of the greatest advantages of linear slide rail bearings. Tight manufacturing tolerances and controlled preload deliver excellent repeatability.

Smooth motion reduces vibration and noise, improving overall machine stability. This is especially important in high-speed or precision-sensitive applications.

Over time, well-maintained linear slide rail bearings maintain their accuracy, supporting consistent product quality.

Types of Linear Slide Rail Bearings

Linear slide rail bearings are available in ball-type, roller-type, and miniature configurations. Each type serves a specific purpose.

Ball-type bearings are widely used in automation and general machinery. Roller-type bearings excel in high-load and high-rigidity applications. Miniature bearings support compact devices such as medical instruments.

YH Linear provides a complete range to meet diverse industrial needs.

Installation and Alignment Best Practices

Proper installation is essential for maximizing bearing performance. Mounting surfaces must be flat, rigid, and accurately machined.

Alignment ensures even load distribution and smooth motion. Misalignment increases wear and reduces service life.

Following manufacturer guidelines ensures that linear slide rail bearings perform as intended.

Applications of Linear Slide Rail Bearings

Linear slide rail bearings are used across many industries. In automation, they support smooth pick-and-place operations. In CNC machines, they ensure cutting accuracy.

Medical equipment relies on quiet, precise motion. Electronics and semiconductor manufacturing demand clean and vibration-free movement.

From light-duty devices to heavy industrial machinery, linear slide rail bearings adapt to diverse environments.

YH Linear Linear Slide Rail Bearings

YH Linear specializes in high-quality linear slide rail bearings designed for precision and durability. Each product reflects strict quality standards and real-world application experience.

By combining advanced manufacturing with responsive technical support, YH Linear delivers reliable motion solutions that perform consistently over time.

Choosing YH Linear means choosing engineering confidence and long-term value.

Future Trends in Linear Slide Rail Bearings

The future of linear slide rail bearings includes smart monitoring and improved materials. Sensor integration will allow predictive maintenance and condition monitoring.

Enhanced coatings and optimized designs will further reduce friction and extend service life. YH Linear continues to innovate to meet evolving industry demands.

FAQs

What are linear slide rail bearings used for?

They guide components in straight-line motion with low friction and high accuracy.

How do linear slide rail bearings differ from plain slides?

They use rolling elements, reducing friction and wear.

Can linear slide rail bearings handle heavy loads?

Yes, especially roller-type designs.

Do linear slide rail bearings need lubrication?

Yes, proper lubrication ensures smooth motion and long service life.

Are linear slide rail bearings suitable for harsh environments?

With proper seals and coatings, they perform reliably.

Why choose YH Linear linear slide rail bearings?

YH Linear offers quality manufacturing, technical expertise, and dependable performance.

Conclusion

Linear slide rail bearings are fundamental to modern precision motion systems. Their ability to deliver smooth, accurate, and reliable movement has made them indispensable across industries.

With proven expertise and a commitment to quality, YH Linear continues to support manufacturers worldwide with dependable linear slide rail bearing solutions. Investing in the right bearings today ensures precision and productivity tomorrow.

Suggested Internal Links

YH Linear linear guide product pages

YH Linear technical articles on motion control

Suggested Outbound Links

Industrial bearing standards organizations

Automation and machine design resources