Comprehensive Outline

| Main Topics | Detailed Coverage |

|---|---|

| Linear Rails CNC Overview | Definition and CNC relevance |

| Evolution of CNC Motion Systems | From box ways to linear rails |

| Linear Rails CNC Fundamentals | Motion principles |

| Core Components | Rail, block, rolling elements |

| Materials and Heat Treatment | Strength and wear resistance |

| Load Capacity in CNC Machines | Cutting forces and rigidity |

| Accuracy and Repeatability | Machining precision |

| Types of Linear Rails CNC | Ball type and roller type |

| Linear Rails CNC vs Box Ways | Performance comparison |

| Installation on CNC Machines | Mounting and alignment |

| Preload and Rigidity Control | Vibration reduction |

| Lubrication for CNC Rails | Continuous operation needs |

| Maintenance and Service Life | Long-term stability |

| High-Speed CNC Machining | Dynamic performance |

| CNC Milling Applications | Surface finish improvement |

| CNC Turning Centers | Axis stability |

| CNC Grinding Machines | Micron-level accuracy |

| Automation and CNC Integration | Tool changers and gantries |

| Selecting Linear Rails CNC | Technical considerations |

| Common CNC Rail Mistakes | Oversizing and misalignment |

| Cost Efficiency in CNC Systems | ROI analysis |

| YH Linear Linear Rails CNC | Brand strengths |

| Future Trends in CNC Rails | Smart and high-rigidity rails |

Introduction

In modern manufacturing, precision is not optional. It is a requirement. Linear rails CNC systems play a decisive role in ensuring that CNC machines deliver consistent accuracy, smooth motion, and reliable performance. Whether used in milling machines, lathes, or machining centers, linear rails CNC technology directly affects machining quality and productivity.

At YH Linear, years of experience working with CNC builders and end users have shown one clear fact. The right linear rails CNC solution can transform machine behavior. Faster feed rates, better surface finishes, and reduced maintenance are often immediate results. This article explores how linear rails CNC systems work, why they matter, and how YH Linear supports precision machining worldwide.

Linear Rails CNC

Linear rails CNC are precision guidance systems used in CNC machines to support and guide moving axes with minimal friction. Unlike traditional sliding ways, linear rails CNC systems rely on rolling elements, usually balls or rollers, that move along hardened raceways.

This rolling contact design dramatically reduces friction. As a result, CNC machines achieve smoother motion, higher speeds, and improved positioning accuracy. Linear rails CNC systems also maintain consistent performance over long operating periods, even under continuous cutting loads.

For CNC manufacturers, linear rails CNC are not just components. They are core elements that define machine capability and reliability.

Evolution of CNC Motion Systems

Early CNC machines relied heavily on box ways and dovetail slides. While robust, these systems suffered from high friction and limited speed. Over time, the demand for faster and more precise machining pushed engineers toward rolling guidance systems.

The introduction of linear rails CNC marked a turning point. Machines became more dynamic, capable of rapid acceleration and deceleration without sacrificing accuracy. Maintenance requirements also dropped, improving machine uptime.

Today, most high-performance CNC machines depend on linear rails CNC technology to meet modern production demands.

Engineering Principles Behind Linear Rails CNC

The primary principle behind linear rails CNC is rolling friction reduction. Balls or rollers circulate within the rail block, ensuring smooth and consistent motion along the axis.

Preload is another key principle. By applying internal pressure, linear rails CNC systems eliminate clearance. This increases rigidity and minimizes vibration during cutting operations.

Load distribution also matters. CNC cutting forces act in multiple directions. Linear rails CNC systems are designed to handle vertical loads, lateral forces, and moment loads simultaneously. This balanced load handling ensures stable machining under demanding conditions.

Core Components of Linear Rails CNC Systems

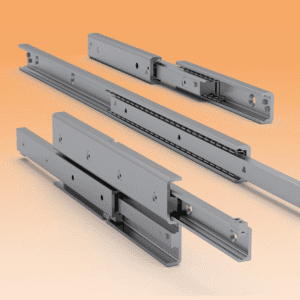

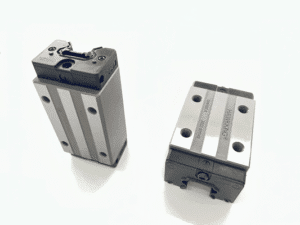

A typical linear rails CNC system includes the rail, the block, rolling elements, seals, and lubrication channels.

The rail is manufactured from hardened steel and precision-ground to maintain straightness. The block houses the rolling elements and transfers load between the moving axis and the rail.

Seals protect the system from chips and coolant, while lubrication ports ensure smooth long-term operation. At YH Linear, each component is carefully engineered to withstand harsh CNC environments.

Materials and Heat Treatment

Material quality directly affects the performance of linear rails CNC. High-strength alloy steel is commonly used to ensure rigidity and wear resistance.

Heat treatment processes, such as induction hardening, improve surface durability while maintaining core toughness. This balance allows linear rails CNC systems to endure heavy cutting forces without deformation.

YH Linear applies strict material and heat-treatment standards to ensure consistent product quality.

Load Capacity and Rigidity in CNC Machines

CNC machining generates significant forces. Linear rails CNC systems must absorb these loads without compromising accuracy.

Roller-type linear rails CNC offer superior rigidity due to line contact between rollers and raceways. Ball-type systems provide excellent speed and precision for light to medium cutting loads.

Selecting the correct rail size and type is essential. YH Linear supports customers with load calculations to ensure optimal performance.

Accuracy and Repeatability in CNC Machining

Accuracy defines CNC performance. Linear rails CNC systems deliver micron-level positioning accuracy and excellent repeatability.

This precision ensures consistent part dimensions, reduced scrap rates, and improved surface finish. Over long production runs, linear rails CNC maintain alignment and smooth motion.

For industries where tolerance control is critical, these systems are indispensable.

Types of Linear Rails CNC

Linear rails CNC systems are available in ball-type and roller-type designs. Ball-type rails are widely used for general-purpose CNC machines.

Roller-type rails are preferred in heavy-duty machining centers due to their higher rigidity. Miniature linear rails CNC serve compact machines and specialized equipment.

YH Linear offers a complete range to meet diverse CNC requirements.

Linear Rails CNC vs Box Ways

Compared to box ways, linear rails CNC systems offer lower friction, higher speed, and better positioning accuracy. Box ways, however, provide excellent damping and load capacity.

Many modern CNC designs combine linear rails CNC with structural damping solutions to achieve the best of both worlds. The choice depends on application needs and machining priorities.

Installation and Alignment on CNC Machines

Proper installation ensures the full performance of linear rails CNC systems. Mounting surfaces must be flat, rigid, and accurately machined.

Alignment between rails is critical. Misalignment increases wear and reduces machining accuracy. Following installation guidelines prevents premature failure.

YH Linear provides technical guidance to support correct installation.

Lubrication and Maintenance

CNC machines often operate continuously. Proper lubrication is essential to protect linear rails CNC systems from wear and corrosion.

Automatic lubrication systems are commonly used to ensure consistent oil or grease supply. Regular inspection further extends service life.

With correct maintenance, linear rails CNC systems operate reliably for years.

Applications of Linear Rails CNC

Linear rails CNC are used in milling machines, turning centers, grinding machines, and gantry systems. They support smooth axis motion and high-speed machining.

In automated CNC cells, linear rails CNC enable precise tool changes and material handling. Their versatility supports a wide range of machining applications.

YH Linear Linear Rails CNC

YH Linear delivers high-performance linear rails CNC designed for precision machining. Each product reflects strict quality control and real-world CNC experience.

By combining reliable manufacturing with responsive technical support, YH Linear helps customers achieve consistent machining results. Choosing YH Linear means choosing stability, accuracy, and long-term value.

Future Trends in Linear Rails CNC

Future linear rails CNC systems will integrate sensors for condition monitoring. Improved coatings and optimized designs will further enhance speed and rigidity.

As CNC machining continues to evolve, linear rails CNC technology will remain central to innovation. YH Linear continues to invest in advanced solutions to meet future demands.

FAQs

What are linear rails CNC used for?

They guide CNC machine axes with high accuracy and low friction.

Are linear rails CNC better than box ways?

They offer higher speed and precision, though box ways provide better damping.

Which type of linear rails CNC is best for heavy cutting?

Roller-type linear rails CNC provide higher rigidity.

Do linear rails CNC need lubrication?

Yes, regular lubrication ensures smooth motion and long service life.

Can linear rails CNC handle coolant exposure?

With proper seals and coatings, they perform well in CNC environments.

Why choose YH Linear linear rails CNC?

YH Linear combines quality manufacturing, CNC expertise, and dependable performance.

Conclusion

Linear rails CNC systems are essential for modern precision machining. They deliver the speed, accuracy, and reliability demanded by today’s CNC machines. From milling to grinding, their influence on machining quality is undeniable.

With proven expertise and a commitment to excellence, YH Linear continues to support CNC manufacturers and users with high-quality linear rails CNC solutions. Investing in the right rails today ensures machining success tomorrow.

Suggested Internal Links

Suggested Outbound Links

CNC machining technology resources

Industrial motion control standards organizations