Introduction

In modern machinery and automation systems, precise, stable, and repeatable linear motion is essential. Linear tracks are fundamental mechanical components that guide and support this motion across a wide range of applications, from CNC machines and industrial automation to robotics, material handling, and consumer equipment.

A linear track provides a defined path along which a moving element—such as a carriage, bearing block, or wheel assembly—travels with controlled accuracy. When paired with bearings or rollers, linear tracks ensure smooth motion, low friction, and high positional accuracy, even under heavy loads.

This article offers a comprehensive overview of linear tracks, covering their definition, types, construction, working principles, advantages, applications, selection criteria, installation, maintenance, and future trends.

What Are Linear Tracks?

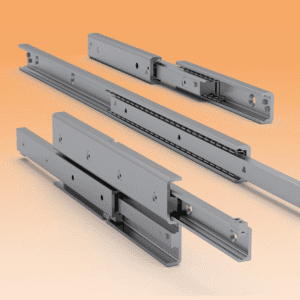

Linear tracks are mechanical guiding elements designed to support and direct motion in a straight line. They serve as the guiding surface or pathway for moving components such as linear bearings, rollers, wheels, or sliding blocks.

Linear tracks can be:

Precision-machined metal rails

Extruded aluminum tracks

Hardened steel guideways

Profiled rails with integrated raceways

Their primary purpose is to maintain alignment, reduce friction, and support loads during linear movement.

How Linear Tracks Work

Linear tracks function by providing a controlled linear path for moving components:

A track is mounted on a rigid base or machine frame.

A carriage, bearing block, or roller assembly engages with the track.

Motion occurs through rolling or sliding contact along the track surface.

Loads are transferred from the moving element to the track.

Smooth, accurate, and repeatable linear motion is achieved.

Depending on the system design, motion may be driven manually or by motors using ball screws, belts, racks, or linear motors.

Key Components of Linear Track Systems

1. Linear Track / Rail

Provides the guiding path

Typically hardened or surface-treated for durability

Ensures straightness and rigidity

2. Carriage or Bearing Block

Moves along the track

Supports loads and maintains alignment

May use rolling or sliding elements

3. Rolling Elements or Sliding Surfaces

Balls, rollers, or low-friction liners

Reduce friction and wear

4. Mounting Hardware

Bolts, clamps, or brackets

Secure the track to the machine frame

5. Seals and Covers (Optional)

Protect tracks from dust and debris

Extend service life in harsh environments

Types of Linear Tracks

1. Precision Linear Guide Tracks

Hardened steel rails with integrated raceways

Used with linear bearing blocks

High accuracy and load capacity

2. Roller Linear Tracks

Designed for wheel or roller carriages

Suitable for heavy loads and long travel distances

Common in material handling systems

3. Aluminum Linear Tracks

Lightweight and corrosion-resistant

Often used in automation and modular systems

Can integrate V-groove or T-slot designs

4. Sliding Linear Tracks

Use low-friction sliding materials

Simpler and cost-effective

Suitable for light-duty applications

5. Heavy-Duty Linear Tracks

Thick, reinforced steel construction

Designed for high loads, shock, and vibration

Used in industrial machinery and gantry systems

Materials and Surface Treatments

Hardened Steel – High load capacity and wear resistance

Stainless Steel – Corrosion resistance in humid or clean environments

Aluminum Alloy – Lightweight and modular design flexibility

Engineering Plastics – Low noise and chemical resistance

Surface Treatments – Induction hardening, chrome plating, anodizing, or black oxide

Material selection depends on load requirements, environmental conditions, and accuracy needs.

Advantages of Linear Tracks

High Precision and Repeatability – Maintains consistent motion paths

Low Friction – Smooth operation with rolling or sliding contact

High Load Capacity – Supports static and dynamic loads

Modular Design – Easy integration into machine systems

Durability – Long service life with proper maintenance

Versatility – Suitable for horizontal, vertical, or inclined motion

Applications of Linear Tracks

CNC Machines – Machine tool axes and gantry systems

Industrial Automation – Assembly lines and transfer systems

Robotics – Linear axes and positioning systems

Material Handling Equipment – Conveyors, carts, and lifts

Packaging Machinery – High-speed motion systems

Medical and Laboratory Equipment – Precision positioning

Furniture and Consumer Products – Drawer slides and adjustable systems

How to Choose the Right Linear Track

Load Capacity – Weight and dynamic forces

Accuracy and Straightness – Precision requirements

Travel Length – Stroke and rail length

Speed and Acceleration – Motion performance needs

Environmental Conditions – Dust, moisture, chemicals, temperature

Mounting and Space Constraints

Maintenance Requirements

Choosing the right linear track ensures reliable operation and long-term performance.

Installation Best Practices

Mount tracks on flat, rigid, and aligned surfaces

Use correct fastener torque and spacing

Verify straightness and parallelism

Lubricate rolling elements if required

Perform trial runs before full operation

Proper installation is critical for accuracy, load distribution, and durability.

Maintenance and Care

Clean tracks regularly to remove contaminants

Inspect for wear, corrosion, or damage

Lubricate rolling components as needed

Replace worn carriages or track sections promptly

Regular maintenance ensures smooth motion and extended service life.

Linear Tracks vs. Linear Guides

| Feature | Linear Tracks | Linear Guides |

|---|---|---|

| Function | Provide guiding path | Guide + bearing system |

| Precision | Moderate to high | High to very high |

| Load Capacity | Moderate to high | High |

| Complexity | Simple to moderate | Higher |

| Cost | Lower to moderate | Moderate to high |

Linear tracks are often used as part of a broader linear guide system.

Future Trends in Linear Track Technology

Integrated guide-and-track systems

Low-maintenance and sealed designs

Advanced coatings for wear and corrosion resistance

Lightweight composite tracks

Smart monitoring integration

These developments support high-efficiency and automated motion systems.

Frequently Asked Questions (FAQs)

1. What are linear tracks used for?

They guide and support straight-line motion in machinery, automation, and handling systems.

2. Are linear tracks the same as linear rails?

Linear rails are a type of linear track designed for high-precision bearing systems.

3. Can linear tracks handle heavy loads?

Yes, heavy-duty steel tracks are designed for high static and dynamic loads.

4. Do linear tracks require lubrication?

Rolling-based systems require lubrication, while some sliding systems may not.

5. What industries use linear tracks?

CNC machining, automation, robotics, material handling, packaging, and medical equipment.

Conclusion

Linear tracks are essential components in linear motion systems, providing the foundation for smooth, accurate, and reliable movement. From precision CNC machines to heavy-duty industrial equipment, linear tracks support load, alignment, and repeatability across countless applications.

With proper selection, installation, and maintenance, linear tracks deliver long service life, improved efficiency, and consistent motion performance.