Introduction

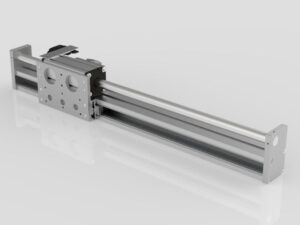

In modern industrial machinery and automation, precision, smoothness, and stability in linear motion are critical. A linear way—also known as a linear guideway—is one of the most important components that ensures accurate linear movement.

Linear ways provide a guiding path for moving parts, allowing carriages or slides to move along a machine frame with minimal friction, high rigidity, and precise alignment. They are widely used in CNC machines, machining centers, robotics, automation lines, and heavy industrial equipment.

This article provides a comprehensive overview of linear ways, including their definition, construction, working principle, types, advantages, applications, selection criteria, installation, and maintenance.

What Is a Linear Way?

A linear way is a mechanical component designed to guide linear motion in a straight path. It typically consists of:

A rail: a hardened, precision-machined track

A carriage or block: a component that moves along the rail

Rolling elements or sliding surfaces: balls, rollers, or low-friction liners

The combination of rail and carriage ensures smooth, accurate, and repeatable motion. Unlike simple sliding surfaces, modern linear ways often incorporate rolling elements to reduce friction and improve load distribution.

How a Linear Way Works

Linear ways operate on a guided motion principle:

The carriage or block moves along the rail.

Rolling elements inside the carriage (balls or rollers) or low-friction surfaces reduce resistance.

The load is evenly distributed along the contact points.

The system maintains high rigidity, accuracy, and repeatability.

The movement is smooth, low-friction, and capable of handling heavy loads.

Linear ways allow machines to operate with high speed, precision, and minimal wear.

Key Components of Linear Ways

1. Rail

Hardened steel or aluminum

Precision-ground for smooth movement

Provides a straight and rigid path

2. Carriage / Block

Supports the load and moves along the rail

Houses rolling elements (balls or rollers)

Ensures stability and alignment

3. Rolling Elements or Sliding Surfaces

Steel balls, cylindrical rollers, or low-friction liners

Reduce friction and wear

Provide smooth, precise motion

4. Retainers and End Caps

Maintain spacing of rolling elements

Enable continuous circulation within the carriage

5. Seals and Wipers

Protect against dust, debris, and liquid contamination

Extend service life

6. Lubrication Channels

Allow grease or oil to maintain smooth operation

Reduce wear and extend durability

Types of Linear Ways

1. Ball Linear Way

Uses recirculating steel balls

Low friction and smooth motion

High precision, suitable for CNC machines and 3D printers

2. Roller Linear Way

Uses cylindrical rollers instead of balls

Higher rigidity and load capacity

Ideal for heavy machinery and gantry systems

3. Profiled Linear Way

Rectangular or square carriage design

Supports multi-directional loads

Common in industrial automation and machining

4. Miniature Linear Way

Compact design for limited spaces

High precision in small machines or laboratory equipment

5. Heavy-Duty Linear Way

Reinforced carriage and large rollers

Designed for extreme loads and shock absorption

Used in steel processing, presses, and heavy CNC equipment

Materials and Surface Treatments

Hardened Steel – High strength, wear resistance

Stainless Steel – Corrosion resistance for wet or clean environments

Aluminum Alloy – Lightweight and modular design

Engineering Plastics / Composites – Low friction, chemical resistance

Surface Treatments – Chrome plating, black oxide, or induction hardening for durability

Material choice depends on load, speed, environmental conditions, and required service life.

Advantages of Linear Ways

High Precision and Repeatability – Maintains accuracy over long periods

Low Friction – Smooth movement with minimal energy consumption

High Load Capacity – Supports heavy static and dynamic loads

High Rigidity and Stability – Resistant to deflection

Long Service Life – Reduced wear and maintenance requirements

Versatile Applications – Horizontal, vertical, or inclined motion

Applications of Linear Ways

CNC Machines – Linear axes and gantry systems

Robotics – Linear axes, positioning stages, and automated arms

Industrial Automation – Assembly lines, material transfer, and packaging

Heavy Machinery – Presses, forging machines, and large-format CNC systems

Medical Equipment – High-precision laboratory instruments

Material Handling Systems – Conveyors, transfer carts, and lifts

Linear Ways vs. Sliding Ways

| Feature | Linear Way | Sliding Way |

|---|---|---|

| Friction | Very low (ball/roller) | Higher (plain surfaces) |

| Load Capacity | High | Moderate |

| Precision | High | Moderate |

| Rigidity | High | Moderate |

| Maintenance | Low | High |

Linear ways are preferred in high-speed, high-precision applications, while traditional sliding ways are suitable for light-duty or low-speed machines.

Choosing the Right Linear Way

Load Capacity – Static, dynamic, and moment loads

Precision Requirements – Accuracy and repeatability

Stroke Length / Travel Distance

Speed and Acceleration

Environmental Conditions – Dust, moisture, temperature, chemicals

Installation Space – Dimensions and mounting constraints

Maintenance Accessibility

Correct selection ensures maximum performance, durability, and minimal downtime.

Installation Best Practices

Mount rails on flat, rigid surfaces

Align carriages carefully to avoid uneven wear

Torque fasteners according to manufacturer recommendations

Apply lubrication before initial operation

Test under load to verify smooth movement

Maintenance Tips

Regularly clean rails and carriages

Inspect rolling elements, seals, and wipers

Re-lubricate according to operating conditions

Replace worn components promptly

Routine maintenance ensures long-term precision and performance.

Future Trends in Linear Way Technology

Heavy-duty, low-maintenance designs

Corrosion-resistant and coated linear ways

Compact, high-precision miniature systems

Smart monitoring and IoT integration

Higher load capacity and stiffness for automated manufacturing

Frequently Asked Questions (FAQs)

1. What is a linear way?

A linear way is a mechanical guide system that allows precise linear motion, typically consisting of a rail and a moving carriage.

2. How is a linear way different from a linear guide?

“Linear way” emphasizes the guiding path, while “linear guide” often includes a carriage with bearings for low-friction motion.

3. Do linear ways require lubrication?

Yes, lubrication is necessary for rolling-element linear ways to reduce wear and extend service life.

4. Can linear ways handle heavy loads?

Yes, roller-type or heavy-duty linear ways are designed for high static and dynamic loads.

5. Where are linear ways commonly used?

CNC machines, automation systems, robotics, heavy industrial machinery, and laboratory equipment.

Conclusion

Linear ways are a cornerstone of precision linear motion systems, offering high rigidity, smooth motion, and load-bearing capability. Their design ensures accuracy, durability, and long service life, making them indispensable in CNC machines, industrial automation, robotics, and heavy machinery.

Proper selection, installation, and maintenance guarantee optimal performance, minimal downtime, and high precision across industrial applications.