Outline

| Headings & Subheadings | LSI / Related Keywords |

|---|---|

| Introduction to Rails and Rollers | linear motion systems, precision movement |

| What Are Rails and Rollers | guide rails, roller mechanisms, motion systems |

| Design and Structure of Rails and Rollers | bearing rollers, guideways, mounting systems |

| How Rails and Rollers Work | linear rolling motion, friction control |

| Major Components of Rails and Rollers | roller carriage, base rail, bearings |

| Types of Rails and Rollers | ball-type, cross roller, cam roller, track roller |

| Advantages of Using Rails and Rollers | stability, precision, longevity |

| Rails and Rollers vs. Linear Guides | friction, stiffness, cost comparison |

| Applications in Modern Industries | automation, CNC, robotics, packaging |

| Choosing the Right Rails and Rollers | load, speed, environment, alignment |

| Materials Used in Rails and Rollers | steel, aluminum, stainless, polymers |

| Installation Tips for Rails and Rollers | alignment, preload, lubrication |

| Common Problems and Fixes | wear, noise, binding, contamination |

| Maintenance Best Practices | cleaning, lubrication, inspection |

| Rails and Rollers in Robotics | compact design, precision, flexibility |

| Advanced Roller Guide Technologies | magnetic, hybrid, self-lubricating |

| Future Innovations | smart sensors, lightweight composites |

| Cost vs. Performance Considerations | durability, efficiency, ROI |

| Top Manufacturers | YH Linear, THK, HIWIN, IGUS |

| FAQs | lifespan, lubrication, installation |

| Conclusion | reliability, performance, innovation |

Introduction to Rails and Rollers

In modern engineering, rails and rollers are essential components that enable machines to move precisely, smoothly, and efficiently. Whether in automated production lines, robotics, or CNC equipment, these systems ensure reliable linear motion with minimal friction.

They form the backbone of linear motion assemblies — allowing components to travel along a guided path under controlled conditions. By combining high load capacity with exceptional precision, rails and rollers have become the standard for applications demanding accuracy and consistency.

Manufacturers such as YH Linear, THK, and HIWIN have elevated these technologies, integrating advanced materials, coatings, and design innovations that redefine durability and performance.

What Are Rails and Rollers

Rails and rollers refer to linear motion mechanisms designed to facilitate straight-line movement. The rail acts as the guideway, providing a precise path, while rollers (cylindrical or needle-like elements) move along it, ensuring smooth motion and distributing loads evenly.

Unlike sliding systems that rely on surface contact, roller-based systems minimize friction using rolling contact — significantly reducing wear and increasing accuracy. This design makes them ideal for applications requiring high rigidity and long-term reliability.

Design and Structure of Rails and Rollers

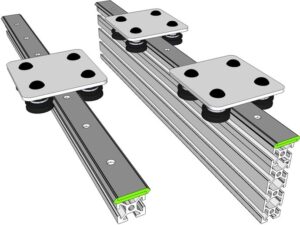

A typical rails and rollers system consists of:

Guide Rail: The fixed track that defines the motion direction.

Roller Carriage: A movable platform with integrated rollers.

Rolling Elements: Cylindrical or spherical rollers that reduce friction.

Retainer or Cage: Holds rollers in place for uniform motion.

End Caps and Seals: Protect from contaminants and retain lubrication.

Mounting Holes: Ensure secure installation to the machine frame.

Each element plays a role in achieving linear stability and motion repeatability.

How Rails and Rollers Work

When force is applied, the rollers move along the rail, translating rotational motion into smooth linear movement. Rolling elements inside the carriage minimize friction between moving parts, providing controlled, efficient motion.

This system distributes loads across multiple rollers, reducing stress on individual contact points. The result is a smooth, consistent travel with minimal backlash — crucial for industries like robotics, semiconductors, and automation.

Major Components of Rails and Rollers

| Component | Description | Function |

|---|---|---|

| Rail | Precision-ground track | Guides linear movement |

| Rollers | Cylindrical rolling elements | Reduce friction and support load |

| Carriage / Block | Movable platform | Transfers motion and supports equipment |

| Seals & Caps | Rubber or polymer covers | Protect from dust and debris |

| Mounting Base | Connection interface | Secures system to structure |

These components combine to create a reliable, long-lasting linear motion system.

Types of Rails and Rollers

Cross Roller Guides: Use crossed cylindrical rollers for ultra-high precision.

Cam Roller Systems: Designed for high-speed and heavy-load operations.

Track Roller Guides: Used in conveyors and material-handling equipment.

Ball Roller Guides: Incorporate ball bearings for smoother, lighter motion.

V-Groove Rollers: Guide along V-shaped tracks, ideal for compact setups.

Each type is suited to specific environments and motion requirements.

Advantages of Using Rails and Rollers

High Precision and Repeatability – Ideal for CNC and robotic systems.

Low Friction – Rolling contact ensures energy efficiency.

Excellent Load Capacity – Handles heavy axial and radial loads.

Durability – Hardened steel rails resist wear and corrosion.

Versatile Design – Works horizontally, vertically, or inverted.

Easy Maintenance – Simple to clean and lubricate.

Compact Form Factor – Saves space while maintaining rigidity.

These benefits make rails and rollers the preferred choice for engineers seeking both reliability and precision.

Rails and Rollers vs. Linear Guides

| Feature | Rails and Rollers | Linear Guides |

|---|---|---|

| Motion Mechanism | Rolling cylindrical elements | Recirculating balls |

| Load Capacity | Higher for equivalent size | Medium to high |

| Precision | Very high | High |

| Speed Capability | High-speed operation | Moderate to high |

| Maintenance | Easier, less frequent | Requires regular lubrication |

| Cost | Slightly higher upfront | Lower cost for standard use |

Both systems provide linear motion, but rails and rollers excel when rigidity and high load-bearing are crucial.

Applications in Modern Industries

CNC Machining: For tool head and gantry positioning.

Automation Equipment: Smooth linear motion in assembly lines.

Robotics: Movement in robotic arms and end-effectors.

Semiconductor Manufacturing: Precision handling and wafer positioning.

Medical Devices: Motion control in imaging and diagnostic systems.

Packaging and Printing Machines: For repetitive linear operations.

The reliability and precision of rails and rollers make them essential across numerous high-tech sectors.

Choosing the Right Rails and Rollers

| Criteria | Considerations |

|---|---|

| Load Capacity | Choose based on static and dynamic loads. |

| Speed Requirements | Match the roller type to desired velocity. |

| Precision Tolerance | Assess linear accuracy and repeatability. |

| Environment | Dust, temperature, and humidity resistance. |

| Material Type | Use stainless or coated steel for corrosion resistance. |

| Lubrication Needs | Opt for sealed or self-lubricating designs if maintenance is limited. |

Proper selection ensures long service life and consistent performance.

Installation Tips for Rails and Rollers

Mount rails on flat, rigid surfaces.

Ensure perfect alignment to prevent roller binding.

Apply uniform preload for stiffness.

Maintain cleanliness during assembly.

Verify manual motion smoothness before final operation.

A precise installation is key to achieving the full performance potential.

Common Problems and Fixes

| Issue | Possible Cause | Solution |

|---|---|---|

| Vibration or Noise | Contamination or wear | Clean and re-lubricate |

| Uneven Travel | Misalignment | Adjust mounting surfaces |

| Excess Friction | Lack of lubrication | Reapply grease or oil |

| Roller Damage | Overloading | Check design capacity |

| Corrosion | Environmental exposure | Use stainless materials or covers |

Routine checks can prevent most operational issues.

Maintenance Best Practices

Clean rails with lint-free cloths regularly.

Reapply lubricant every 500–1000 operating hours.

Replace worn rollers or seals promptly.

Keep mounting areas dry and debris-free.

Inspect alignment annually for high-precision setups.

Consistent maintenance ensures reliability and optimal efficiency.

Rails and Rollers in Robotics

In robotics, rails and rollers are the cornerstone of precision motion. They enable stable linear travel for robotic arms, axes, and manipulators — ensuring repeatable accuracy. Compact roller systems reduce inertia and improve responsiveness, allowing for smoother, faster automation cycles.

YH Linear’s roller guide solutions, for example, combine lightweight design with exceptional rigidity, perfectly suited for high-speed robotic environments.

Advanced Roller Guide Technologies

Self-Lubricating Systems: Minimize downtime and manual maintenance.

Magnetic Roller Guides: Enable contactless, friction-free motion.

Hybrid Ceramic Rollers: Enhance lifespan and reduce vibration.

Corrosion-Resistant Coatings: Improve performance in harsh settings.

Integrated Sensor Modules: Monitor temperature, wear, and alignment in real-time.

These innovations redefine what’s possible in linear motion technology.

FAQs

What are rails and rollers used for?

They guide and support linear motion in machinery, automation, and robotics.

Do rails and rollers need lubrication?

Yes — lubrication ensures smooth rolling and extends lifespan, though some systems are self-lubricating.

How do I install rails and rollers?

Mount them precisely on flat surfaces, ensure alignment, and test for smooth movement before full operation.

Can they be used vertically?

Absolutely — with correct preload and load orientation, they perform well vertically.

What materials are best for rails and rollers?

Hardened steel for strength, stainless steel for corrosion resistance, and polymers for noise reduction.

Conclusion

Rails and rollers are at the heart of modern motion technology — combining strength, precision, and flexibility in one compact system. Their use in robotics, CNC machines, and automation ensures the perfect blend of durability and performance.

Choosing reliable components from trusted brands like YH Linear guarantees not only precision and longevity but also confidence in every movement your system makes.