Outline

| Headings & Subheadings | LSI / Related Keywords |

|---|---|

| Introduction to Linear Guide Systems | linear motion technology |

| What Are Linear Guide Systems | linear rails, guide blocks |

| Core Components of Linear Guide Systems | rail, carriage, ball recirculation |

| How Linear Guide Systems Work | friction reduction, rolling contact |

| Benefits of Linear Guide Systems | accuracy, rigidity, load capacity |

| Different Types of Linear Guide Systems | roller guides, ball guides |

| Materials and Manufacturing Process | hardened steel, stainless steel |

| Linear Guide Systems vs Traditional Sliding Guides | comparison table |

| Applications of Linear Guide Systems | CNC, robotics, automation |

| Linear Guide Systems in CNC Machines | machining accuracy |

| Key Factors in Selecting Linear Guide Systems | load, speed, environment |

| Heavy-Duty Linear Guide Systems | industrial-grade performance |

| YH Linear: Trusted Supplier of Linear Guide Systems | OEM, customization, quality |

| Installation and Maintenance Tips | alignment, lubrication |

| Common Issues and Troubleshooting | noise, misalignment |

| Innovations in Linear Guide Systems | IoT, self-lubrication |

| Sustainability in Linear Motion Manufacturing | eco-friendly materials |

| Global Market and Major Brands | THK, HIWIN, YH Linear |

| FAQs | lifespan, lubrication, interchangeability |

| Conclusion | performance, efficiency, innovation |

Introduction to Linear Guide Systems

In today’s world of automation, linear guide systems form the backbone of precision motion. These systems ensure smooth, controlled movement across straight paths — whether in CNC machines, industrial robots, or high-speed packaging equipment.

By replacing sliding friction with rolling motion, linear guide systems allow for higher accuracy, efficiency, and durability. They are the invisible yet crucial components that make precision manufacturing and automated assembly possible.

What Are Linear Guide Systems

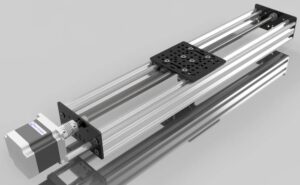

A linear guide system is a mechanical arrangement designed to support and guide motion in a straight line. It typically consists of a guide rail and a bearing block (carriage) containing rolling elements such as balls or rollers.

The bearing block glides along the rail with minimal resistance, maintaining tight tolerances and stability even under heavy loads. These systems are vital in industries where motion precision, repeatability, and smoothness are key — from robotics and aerospace to semiconductor manufacturing.

Core Components of Linear Guide Systems

Each linear guide system comprises precision-engineered components that work together to achieve seamless linear movement:

Guide Rail: The hardened track providing directional stability.

Carriage (Block): Houses rolling elements and connects to the moving structure.

Rolling Elements (Balls or Rollers): Enable smooth rolling contact.

End Caps and Seals: Prevent contamination and retain lubrication.

Retainers or Cages: Ensure even load distribution and smooth motion.

Each part contributes to the overall accuracy and lifespan of the system.

How Linear Guide Systems Work

Linear guide systems operate on a simple but powerful concept: rolling motion.

As the carriage moves, the rolling elements (steel balls or cylindrical rollers) circulate inside the block through return channels. This rolling contact dramatically reduces friction compared to traditional sliding mechanisms.

The result? High efficiency, reduced wear, and precise linear motion — even at high speeds or heavy loads. The smoother the motion, the better the machine’s accuracy and performance.

Benefits of Linear Guide Systems

The advantages of using linear guide systems extend across multiple industries:

High Precision: Maintains micron-level accuracy.

Low Friction: Ensures smooth, energy-efficient motion.

High Load Capacity: Supports both radial and moment loads.

Rigidity and Stability: Ideal for high-speed operations.

Long Service Life: Advanced materials resist wear and corrosion.

Ease of Maintenance: Simple lubrication and alignment.

These features make linear guide systems the preferred choice for modern engineering applications.

Different Types of Linear Guide Systems

Linear guide systems vary based on the type of rolling element and design:

Ball-Type Linear Guides: Use recirculating steel balls; best for precision motion.

Roller-Type Linear Guides: Use cylindrical rollers for higher rigidity and load capacity.

Miniature Linear Guides: Compact and lightweight, ideal for electronics or medical use.

Wide-Type Linear Guides: Provide stability for heavy or off-center loads.

High-Speed Linear Guides: Designed for dynamic industrial applications.

Each type offers unique advantages depending on performance requirements.

Materials and Manufacturing Process

High-performance linear guide systems rely on premium materials and advanced manufacturing:

Hardened Bearing Steel (SUJ2): Ensures wear resistance and dimensional stability.

Stainless Steel: Provides corrosion protection in humid or clean environments.

Precision Grinding: Guarantees straightness and flatness of the rail surface.

Heat Treatment: Improves hardness and fatigue resistance.

Surface Finishing: Adds anti-corrosion and low-friction coatings.

Strict quality control ensures the reliability of every guide system produced.

Linear Guide Systems vs Traditional Sliding Guides

| Feature | Linear Guide System | Traditional Sliding Guide |

|---|---|---|

| Friction | Very low (rolling contact) | High (sliding contact) |

| Speed | High | Limited |

| Precision | Micron-level | Moderate |

| Maintenance | Minimal | Frequent |

| Durability | Long-lasting | Prone to wear |

| Efficiency | Excellent | Lower |

Clearly, linear guide systems outperform traditional sliding mechanisms in virtually every category.

Applications of Linear Guide Systems

The applications for linear guide systems are vast and ever-growing:

CNC Machining Centers

3D Printers and Laser Cutters

Industrial Robotics

Medical Devices

Semiconductor Equipment

Packaging and Printing Machines

Aerospace Test Systems

Their ability to deliver precise, stable motion makes them indispensable to industries built on accuracy.

Linear Guide Systems in CNC Machines

CNC machines rely heavily on linear guide systems to achieve tight tolerances and repeatable results.

These guides ensure that cutting tools and worktables move precisely along predefined axes without deflection or vibration. By reducing friction, they also enhance energy efficiency and surface finish quality.

Whether it’s milling, turning, or laser engraving, CNC performance directly depends on the reliability of its linear guide systems.

Key Factors in Selecting Linear Guide Systems

When choosing the right linear guide system, engineers should consider:

| Factor | Importance |

|---|---|

| Load Rating | Determines how much force the guide can handle |

| Speed and Acceleration | Affects smoothness and stability |

| Precision Grade | Impacts positional accuracy |

| Environment | Corrosive or cleanroom applications require stainless steel |

| Mounting Type | Side, bottom, or top mounting affects rigidity |

| Lubrication Options | Extends lifespan and reduces wear |

Partnering with a specialized manufacturer like YH Linear ensures optimal system selection and long-term reliability.

Heavy-Duty Linear Guide Systems

For demanding applications such as machine tools, presses, and injection molding machines, heavy-duty linear guide systems are essential.

These systems use larger rolling elements, thicker rails, and reinforced carriages to handle extreme loads while maintaining accuracy.

YH Linear’s heavy-duty series exemplifies this balance between strength and precision — offering exceptional rigidity, extended service life, and reliable operation even in harsh industrial conditions.

YH Linear: Trusted Supplier of Linear Guide Systems

YH Linear is a global leader in linear guide systems, offering a comprehensive range of rails, blocks, and motion assemblies.

With advanced production facilities, strict quality control, and customized solutions, YH Linear ensures every product meets international performance standards.

Why engineers choose YH Linear:

OEM & ODM customization services

Competitive pricing with fast lead times

ISO-certified production

Precision machining and testing

Global logistics and after-sales support

From small-scale machinery to industrial automation, YH Linear provides motion systems built for precision and endurance.

Installation and Maintenance Tips

To ensure smooth performance and long lifespan of your linear guide systems:

Clean all surfaces before installation.

Ensure proper alignment between rails.

Apply the correct type and amount of lubricant.

Avoid over-tightening mounting bolts.

Regularly inspect preload and motion smoothness.

Routine care prevents wear, vibration, and noise — keeping systems efficient and reliable.

Common Issues and Troubleshooting

Common problems in linear guide systems include:

Noise or Vibration: Often caused by contamination or misalignment.

Uneven Motion: Can result from incorrect preload or damaged balls.

Corrosion: Preventable through protective coatings or stainless steel.

Short Lifespan: Usually due to improper lubrication or overload.

Most issues can be resolved with regular inspection and preventive maintenance.

Innovations in Linear Guide Systems

The evolution of linear guide systems continues with advancements such as:

Self-Lubricating Bearings

Integrated Sensors for Predictive Maintenance

Lightweight Composite Carriages

Low-Noise Design for Robotics

Smart IoT-Enabled Linear Guides

These innovations enhance efficiency and align with Industry 4.0 automation trends.

Sustainability in Linear Motion Manufacturing

Modern manufacturers are embracing sustainability through:

Recyclable steel alloys

Reduced machining waste

Eco-friendly lubricants

Energy-efficient production lines

YH Linear remains committed to sustainable precision manufacturing, ensuring a balance between performance and environmental responsibility.

Global Market and Major Brands

Key players in the linear guide systems market include:

| Brand | Region | Strengths |

|---|---|---|

| YH Linear | China | OEM service, high precision, affordability |

| THK | Japan | Industry pioneer, innovative technology |

| HIWIN | Taiwan | Cost-effective, reliable solutions |

| NSK | Japan | Advanced precision control |

| Bosch Rexroth | Germany | Automation and heavy-duty systems |

| IKO | Japan | Compact, high-rigidity designs |

Together, these brands define global standards in motion technology.

FAQs

What is a linear guide system used for?

It’s used to support and guide linear motion with precision and low friction.

Are linear guide systems interchangeable between brands?

Most follow ISO and DIN standards, allowing partial interchangeability.

How long do linear guide systems last?

With proper maintenance, they can operate for millions of cycles.

Can linear guides work in dirty environments?

Yes, with protective seals and regular cleaning.

What lubrication should be used?

Use lithium-based or synthetic grease recommended by the manufacturer.

Conclusion

Linear guide systems are the foundation of precision automation, providing the accuracy, rigidity, and stability needed in modern machinery.

Whether you’re designing CNC equipment, robotic arms, or automated production lines, choosing a trusted supplier like YH Linear ensures reliability and long-term performance backed by engineering excellence.