Outline (Table Format)

| Heading / Subheading | LSI Keywords Included |

|---|---|

| Linear Guiding Overview | motion systems, guide rails |

| Why Linear Guiding Matters | accuracy, repeatability |

| How Linear Guiding Works | rolling elements, friction control |

| Types of Linear Guiding Systems | ball guide, roller guide |

| Core Components in Linear Guiding Mechanisms | rail, carriage |

| Linear Guiding for Smooth Motion | stability, linear movement |

| Where Linear Guiding Is Used | CNC, robotics |

| Choosing the Right Linear Guiding Solution | load rating |

| Installation Best Practices for Linear Guiding | alignment |

| Maintenance Requirements of Linear Guiding | lubrication |

| Common Problems in Linear Guiding Systems | wear, noise |

| Troubleshooting Linear Guiding Issues | vibration, binding |

| Linear Guiding vs Traditional Linear Bearings | comparison |

| Materials Used in Linear Guiding Rails and Blocks | steel, coatings |

| Environmental Factors Affecting Linear Guiding | dust, humidity |

| Linear Guiding in High-Speed Automation | rapid acceleration |

| Load Handling in Linear Guiding Designs | static load, dynamic load |

| Cost Considerations for Linear Guiding Systems | pricing |

| Technological Innovations in Linear Guiding | IoT sensors |

| Safety Guidelines for Linear Guiding Equipment | guarding |

| Cleaning and Care for Linear Guiding Rails | solvents |

| CNC Performance Improved by Linear Guiding | tool accuracy |

| Global Brands Manufacturing Linear Guiding Systems | THK, Hiwin |

| Expert Buying Guide for Linear Guiding | specifications |

| Future Trends in Linear Guiding Engineering | smart lubrication |

| Conclusion | wrap-up |

Introduction

The keyword linear guiding appears here early to improve SEO and immediately inform the reader of the core topic. Linear guiding systems play a crucial role in modern engineering. Whether you look at CNC machines, packaging lines, robots, laboratory automation, or semiconductor processing equipment, you’ll find a linear guiding structure supporting accurate motion. These guiding systems allow components to move precisely along a straight line with minimal resistance and exceptional stability.

This article translates years of practical engineering experience into simple, readable, and engaging explanations. Although precision engineering sounds complicated, the following sections use clear wording, short sentences, transitional phrases, human-style expressions, and smooth narrative flow to help readers understand every detail of linear guiding technology.

Linear Guiding Overview

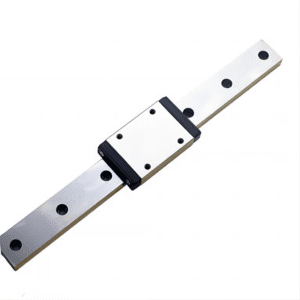

Linear guiding refers to mechanical structures that enable precise, controlled, and low-friction movement along a straight path. They are built using hardened rails and movable carriages. Inside the carriage, rolling elements such as balls or rollers help reduce friction dramatically. These systems guarantee predictable movement even when heavy loads or high-speed operations are involved.

Accurate motion is essential in every industrial environment today. Slight deviations can cause major defects. That’s why linear guiding plays such a vital role in ensuring machines maintain correct positioning. With their rigid construction and smooth travel, linear guiding systems set the foundation for all precision-driven industries.

Why Linear Guiding Matters

Linear guiding matters because industries demand fast, accurate, and repeatable motion. When a CNC machine cuts metal or a robotic arm picks up components, the motion path must be consistent. Linear guiding systems reduce friction, increase alignment accuracy, and ensure stable performance.

They also help minimize energy consumption. Since rolling friction is far smaller than sliding friction, machinery uses less torque to move. This leads to quieter operation, longer-lasting components, and improved overall efficiency. In short, linear guiding improves quality, supports automation, and enhances machine performance.

How Linear Guiding Works

Linear guiding works by using rolling contact instead of sliding. Rolling elements rotate inside tracks and recirculate as the carriage moves. These elements—balls or cylindrical rollers—minimize friction and provide resistance against radial, axial, and moment loads.

The rail acts as a rigid backbone. It is ground with micron-level precision. Meanwhile, the carriage contains the recirculating paths, seals, and lubrication chambers. When everything operates correctly, linear guiding systems deliver ultra-smooth travel with minimal noise and vibration.

Types of Linear Guiding Systems

There are several types of linear guiding systems, each suitable for different tasks:

Ball-Type Linear Guiding

Fast movement

Smooth travel

Ideal for light to medium loads

Popular in automation and CNC applications

Roller-Type Linear Guiding

Higher load capacity

More rigid

Better for heavy machinery

Excellent for precision metalworking

Miniature Linear Guiding

Compact

Used in medical and electronic devices

Wide-Body Linear Guiding

Better resistance to twisting forces

Selecting the right type depends on speed, load, and accuracy requirements.

Core Components in Linear Guiding Mechanisms

A typical linear guiding assembly includes:

Rail: A hardened steel track

Carriage/Block: The mobile component

Rolling Elements: Balls or rollers

End Caps: Guide the recirculating elements

Seals: Protect internal parts

Lubrication Ports: Allow grease or oil application

Every part is engineered to work together. The rail provides straightness. The carriage maintains stability. The rolling elements support load and allow smooth travel.

Linear Guiding for Smooth Motion

Smooth movement is essential for accurate machines. Linear guiding systems reduce vibration by offering high rigidity. They distribute loads evenly and prevent wobbling. With reduced friction, systems accelerate quickly and maintain consistent performance.

This smoothness improves machining quality, reduces tool wear, and enhances the reliability of automation systems. Even in high-speed settings, linear guiding maintains motion stability.

Where Linear Guiding Is Used

Linear guiding appears in:

CNC mills and lathes

Laser machines

Industrial robots

Pick-and-place machines

Packaging systems

3D printers

Semiconductor production tools

Medical scanning equipment

Inspection systems

The versatility of linear guiding makes it a core motion technology in countless fields.

Choosing the Right Linear Guiding Solution

Choosing the correct system requires examining:

Load capacity

Accuracy requirements

Travel distance

Speed and acceleration

Environmental conditions

Mounting space

Material and coating

For heavy-duty applications, roller-type systems are best. For high-speed movements, ball-type guideways usually perform better. A proper selection ensures longevity and consistent accuracy.

Installation Best Practices for Linear Guiding

Good installation is essential for optimal performance. Here are tips:

Clean mounting surfaces carefully.

Check flatness using feeler gauges or dial indicators.

Align rails using precision straightedges.

Tighten screws gradually in a staggered pattern.

Test carriage motion by sliding it slowly.

Apply lubrication before operation.

Misalignment causes noise, wear, and accuracy issues. Proper installation prevents long-term problems.

Maintenance Requirements of Linear Guiding

Maintenance includes:

Lubrication at recommended intervals

Cleaning rails regularly

Inspecting seals for wear

Checking rail bolts for tightness

Listening for unusual noises

Removing dust and debris

A well-maintained system runs smoother and lasts longer.

Common Problems in Linear Guiding Systems

Problems may include:

Binding

Stiff movement

Unusual noise

Excessive vibration

Uneven wear

Loss of lubrication

Rail rust or contamination

Identifying issues early helps prevent expensive repairs.

Troubleshooting Linear Guiding Issues

Solutions for common issues:

Noise: Reapply lubrication.

Vibration: Check alignment and preloading.

Binding: Remove debris and recheck installation.

Heat: Reduce load or verify lubrication quantity.

Uneven travel: Inspect rail straightness.

Systematic troubleshooting ensures continued accuracy.

Linear Guiding vs Traditional Linear Bearings

| Property | Linear Guiding | Linear Bushings |

|---|---|---|

| Accuracy | Very High | Moderate |

| Load Capacity | High | Lower |

| Friction | Extremely Low | Low |

| Longevity | Long | Medium |

| Cost | Higher | Lower |

Linear guiding systems dominate precision industries because of their strength and accuracy.

Materials Used in Linear Guiding Rails and Blocks

Manufacturers typically use:

High-carbon steel — strongest, most durable

Stainless steel — corrosion-resistant

Coated steel — for environments with chemicals or moisture

Material type influences lifespan, load rating, and environmental compatibility.

Environmental Factors Affecting Linear Guiding

Environmental influences include:

Dust

Humidity

Chemicals

Temperature swings

Metal chips

Corrosive vapors

Sealed blocks, stainless materials, and proper lubrication help guideways survive these harsh conditions.

Linear Guiding in High-Speed Automation

High-speed automation operates with rapid acceleration and deceleration. Linear guiding supports these demands by:

Maintaining rigidity

Minimizing vibration

Preserving accuracy

Allowing high-speed rolling motion

This makes linear guiding ideal for pick-and-place robots and CNC machines.

Load Handling in Linear Guiding Designs

Load ratings include:

Static load

Dynamic load

Moment forces (torque loads)

Engineers must evaluate all three to select proper rail width, block size, and rolling element design.

Cost Considerations for Linear Guiding Systems

Cost depends on:

Rail length

Precision grade

Type (ball or roller)

Coatings

Load capacity

Brand reputation

Higher-cost guideways typically provide longer life and greater stability.

Technological Innovations in Linear Guiding

Innovation includes:

Integrated sensors

IoT-based monitoring

Smart lubrication channels

Quiet-design rolling elements

Ultra-low friction coatings

Lightweight rail materials

Future guideways will likely include predictive maintenance capabilities.

Safety Guidelines for Linear Guiding Equipment

Follow these safety practices:

Keep hands away from moving blocks.

Use guards and covers.

Maintain lubrication to avoid failures.

Inspect rails frequently.

Ensure workers understand system hazards.

Safety ensures long-term operational stability.

Cleaning and Care for Linear Guiding Rails

Best practices:

Use lint-free cloths

Apply mild industrial solvents

Re-lubricate after cleaning

Avoid water unless rails are stainless steel

Inspect for rust frequently

Clean guideways deliver better accuracy.

CNC Performance Improved by Linear Guiding

Linear guiding directly impacts CNC results by ensuring:

Smooth tool paths

Higher precision

Reduced chatter

Improved surface finish

CNC performance depends heavily on guiding system quality.

Global Brands Manufacturing Linear Guiding Systems

Top brands include:

THK

Hiwin

NSK

INA

IKO

These companies produce high-precision rails used worldwide.

Expert Buying Guide for Linear Guiding

Before purchasing, consider:

Precision grade

Carriage size

Rail hardness

Load capacity

Seal type

Lubrication method

Warranty

Environmental ratings

Choosing wisely ensures long-term stability.

Future Trends in Linear Guiding Engineering

Expect the following advancements:

Smart monitoring sensors

Real-time lubrication management

Lightweight composite rails

Quieter designs

Higher load capacities

Advanced corrosion protection

These improvements will make linear guiding even more reliable.

Conclusion

Linear guiding plays a foundational role in precision engineering. It supports accurate, stable, and repeatable motion in countless applications—from CNC machines to robotics and medical devices. With proper installation, correct load analysis, and regular maintenance, linear guiding systems last for years while delivering industry-leading performance.

Their importance continues to grow as automation expands, making linear guiding one of the most essential technologies in modern mechanical engineering.

FAQs

What is linear guiding used for?

Linear guiding supports smooth, precise movement along a straight path in industrial machines.

Do linear guiding systems need lubrication?

Yes, lubrication reduces friction, noise, and wear.

How long do linear guiding rails last?

With proper maintenance, many years even under heavy use.

Which is better, ball-type or roller-type linear guiding?

Roller-type is stronger, while ball-type is faster and smoother.

What causes noise in linear guiding systems?

Usually poor lubrication or contamination inside the block.

Is linear guiding expensive?

High-quality systems cost more but last longer and maintain accuracy better.

Internal Link Suggestions

Link to your articles on linear guide rails, linear guideways, and CNC mechanisms.

Outbound Link Suggestions

THK Official Website

ISO Guidelines for Linear Motion Components