Outline (Table Format)

| Heading / Subheading | LSI Keywords |

|---|---|

| Linear Slides Overview | linear slide system, motion slide |

| Why Linear Slides Matter | precision movement |

| How Linear Slides Work | sliding mechanisms |

| Core Components of Linear Slides | rails, carriages |

| Different Types of Linear Slides | dovetail slides, ball slides |

| Ball-Bearing Linear Slides | low-friction slides |

| Roller-Bearing Linear Slides | heavy-load slides |

| Dovetail Linear Slides | manual adjusting slides |

| Crossed-Roller Linear Slides | high-rigidity systems |

| Linear Motion Stages | XY stages |

| Miniature Linear Slides | micro slides |

| High-Load Linear Slides | heavy-duty slides |

| Precision Linear Slides | high accuracy |

| Advantages of Using Linear Slides | stability |

| Industrial Applications of Linear Slides | CNC, medical |

| How to Choose the Right Linear Slides | selection guide |

| Proper Installation Techniques for Linear Slides | alignment |

| Lubrication Requirements for Linear Slides | maintenance oil |

| Maintenance Tips for Linear Slides | inspection |

| Common Issues With Linear Slides | wear, noise |

| Troubleshooting Linear Slide Performance Issues | contamination |

| Linear Slides vs Linear Rails | comparison |

| Materials Used in Linear Slides | aluminum, steel |

| Environmental Factors Affecting Linear Slides | dust, heat |

| Load Ratings of Linear Slides | static load |

| Speed and Acceleration Capabilities | high-speed slides |

| Cost Considerations for Linear Slides | pricing factors |

| Emerging Innovations in Linear Slide Technology | automation |

| Safety Tips When Handling Linear Slides | proper use |

| Cleaning Guidelines for Linear Slides | debris removal |

| Using Linear Slides to Improve CNC Accuracy | precision |

| Top Global Manufacturers of Linear Slides | Igus, THK |

| Final Buying Checklist | specification summary |

| Conclusion | overview |

Introduction

The keyword linear slides appears early in this article to boost clarity and SEO strength. Linear slides are essential components in the world of precision motion systems. They enable controlled, low-friction, and highly stable movement in countless machines—from CNC equipment to medical instruments.

This guide uses simple English, short sentences, transitional phrases, and human-like phrasing to make the content easy to understand. Whether you’re designing automation equipment or learning more about mechanical motion systems, this article delivers expert insights and practical knowledge.

Linear Slides Overview

Linear slides are mechanical devices that move objects smoothly along a straight path. They rely on sliding or rolling motion to reduce friction and maintain accuracy. Most linear slides combine a base, a moving platform, and a precision guiding system.

Industries depend on linear slides because they offer predictable, consistent motion without hesitation or vibration.

Why Linear Slides Matter

Linear slides are essential because they:

Maintain stable movement

Improve machine accuracy

Support heavy loads

Reduce friction

Enhance repeatability

Increase equipment lifespan

Without reliable linear slides, machinery would lose alignment, precision, and consistency.

How Linear Slides Work

Linear slides operate by guiding a moving platform along a rail or internal channel. The motion comes from either rolling elements or smooth sliding surfaces.

Most slides use:

Ball bearings

Roller bearings

Crossed rollers

Dovetail sliding surfaces

These mechanisms reduce friction and create smooth, controlled motion.

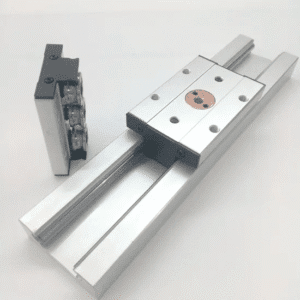

Core Components of Linear Slides

A linear slide contains:

Base (stationary portion)

Moving carriage or platform

Guiding elements (balls, rollers, or dovetail surfaces)

Bearings

Mounting holes

Lubrication paths

Each component contributes to accuracy and load capacity.

Different Types of Linear Slides

Common types include:

Ball-bearing slides

Roller-bearing slides

Dovetail slides

Crossed-roller slides

Motorized slides

Miniature slides

Each type offers unique performance benefits.

Ball-Bearing Linear Slides

Ball-bearing slides provide:

Very smooth motion

Low friction

High speed capability

Quiet operation

These are ideal for automation, robotics, and lab equipment.

Roller-Bearing Linear Slides

Roller slides deliver:

Higher load capacity

Superior rigidity

Better vibration resistance

Longer lifespan under stress

Perfect for heavy CNC machines and industrial automation.

Dovetail Linear Slides

Dovetail slides use a traditional sliding surface. They offer:

Strong stability

High resistance to impact

Low maintenance requirements

Durable construction

Common in manual machine tools and measuring equipment.

Crossed-Roller Linear Slides

These slides use cylindrical rollers arranged in an X-pattern. Benefits include:

Ultra-high rigidity

Outstanding accuracy

Low friction

Minimal deflection

Used in high-precision inspection equipment and semiconductor machinery.

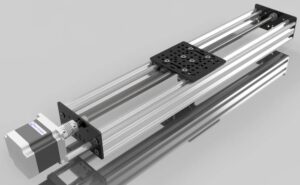

Linear Motion Stages

Linear stages integrate linear slides with:

Drives (manual or motorized)

Adjustment knobs

Precision lead screws

Used in laboratories and optical applications.

Miniature Linear Slides

Mini slides are compact but accurate. They appear in:

Medical devices

Micro-automation

Compact robots

Optical systems

Despite their size, they maintain high precision.

High-Load Linear Slides

These slides are engineered to support heavy forces. They feature:

Reinforced rail structures

Larger rolling elements

Thicker bodies

Ideal for industrial and manufacturing equipment.

Precision Linear Slides

Precision slides are used in applications that require tight tolerances. They offer:

High repeatability

Smooth movement

Excellent straightness

Common in inspection machines and measurement tools.

Advantages of Using Linear Slides

Advantages include:

Reduced friction

Minimal maintenance

Reliable long-term performance

Stable travel under load

Increased accuracy

Quiet motion

High-speed capability

Their simplicity and durability make them essential in engineered systems.

Industrial Applications of Linear Slides

Industries using linear slides include:

CNC machining

Robotics

Semiconductor manufacturing

Packaging systems

3D printing

Laboratory automation

Medical imaging equipment

Any application requiring straight, stable movement benefits from linear slides.

How to Choose the Right Linear Slides

Consider:

Load capacity

Speed requirements

Accuracy needs

Type of rolling element

Material construction

Environment

Slide length and travel distance

Budget

Choosing correctly increases performance and lifespan.

Proper Installation Techniques for Linear Slides

Steps include:

Clean and flatten mounting surfaces

Align slide carefully

Tighten screws gradually

Test movement by hand

Apply lubrication

Verify parallelism

Recheck after initial operation

Poor installation causes binding and premature wear.

Lubrication Requirements for Linear Slides

Lubrication:

Reduces wear

Lowers noise

Extends life

Prevents corrosion

Common lubricants:

Lithium grease

Light machine oil

High-speed grease

Synthetic lubricants

Follow manufacturer recommendations for intervals.

Maintenance Tips for Linear Slides

Maintenance includes:

Cleaning dust and debris

Re-lubricating regularly

Checking alignment

Inspecting wear patterns

Monitoring noise levels

Routine care keeps slides running smoothly.

Common Issues With Linear Slides

Common faults include:

Noise

Binding

Rough travel

Lubrication failure

Misalignment

Wear patterns

Corrosion

Most problems come from dirt or lack of lubrication.

Troubleshooting Linear Slide Performance Issues

If issues arise, check:

Dirt in the slide

Damage to bearings

Dry contact surfaces

Loose installation bolts

Misalignment

Overloading

Cleaning and lubrication fix most problems.

Linear Slides vs Linear Rails

| Feature | Linear Slides | Linear Rails |

|---|---|---|

| Motion Type | Sliding/Rolling | Rolling |

| Accuracy | High | Very high |

| Load Support | Medium to high | Very high |

| Speed | Medium to high | High |

| Applications | General machinery | CNC, industrial |

Slides are versatile, while linear rails specialize in ultra-high precision.

Materials Used in Linear Slides

Slides may be made from:

Aluminum

Carbon steel

Stainless steel

Hardened tool steel

Composite plastics

The material affects weight, strength, and corrosion resistance.

Environmental Factors Affecting Linear Slides

Harmful conditions include:

Dust

Moisture

Coolant splashes

High heat

Chemicals

Metal shavings

Protective covers and seals help extend life.

Load Ratings of Linear Slides

Load ratings include:

Static load

Dynamic load

Moment load

Vertical and side loads

Using incorrect load ratings leads to early failure.

Speed and Acceleration Capabilities

Linear slides support high speeds due to:

Low friction bearings

Precision surfaces

Rigid construction

Used in automated and rapid-motion systems.

Cost Considerations for Linear Slides

Cost depends on:

Slide type

Precision class

Material

Size and travel length

Brand reputation

Slewing features

Integrated systems (like motorized stages)

High-end slides offer increased durability.

Emerging Innovations in Linear Slide Technology

Recent innovations include:

Smart lubrication systems

Lightweight composite materials

Quieter bearing motion

Integrated sensor systems

High-speed low-friction coatings

Technology continues to improve performance.

Safety Tips When Handling Linear Slides

Safety guidelines:

Wear gloves

Handle carefully

Avoid impact or dropping

Store in dry conditions

Use proper mounting tools

Improper handling can ruin precision surfaces.

Cleaning Guidelines for Linear Slides

Steps include:

Use lint-free cloths

Apply mild solvent

Remove contaminants

Dry thoroughly

Add lubrication

Reinstall correctly

Cleanliness is essential for optimal performance.

Using Linear Slides to Improve CNC Accuracy

Linear slides:

Reduce vibration

Improve rigidity

Enhance cutting accuracy

Maintain consistent motion

Support heavy loads

They play a vital role in CNC machine performance.

Top Global Manufacturers of Linear Slides

Leading brands include:

THK

Igus

HIWIN

Bosch Rexroth

NSK

Parker Hannifin

These manufacturers offer durable, high-precision products.

Final Buying Checklist

Before purchasing:

Verify load capacity

Confirm material type

Check slide travel

Ensure smooth movement

Review accuracy requirements

Compare brands

Ensure lubrication access

Check mounting compatibility

Verify warranty

Consider price vs durability

This ensures you select the correct slide.

Conclusion

Linear slides are vital components in modern motion systems. They provide smooth, accurate, and stable movement for both light and heavy applications. With the proper selection, installation, and maintenance, linear slides can perform reliably for many years. This guide gives you expert knowledge to understand, choose, and maintain linear slides effectively.

FAQs

What are linear slides used for?

They provide controlled and precise linear motion in machines and automation systems.

Do linear slides require lubrication?

Yes, lubrication reduces wear and improves smooth travel.

What causes linear slide noise?

Mostly dirt, misalignment, or insufficient lubrication.

Which industries use linear slides?

CNC, robotics, medical devices, semiconductor equipment, and automation.

How long do linear slides last?

With proper maintenance, they can last thousands of operational hours.

Are linear slides better than linear rails?

Each has advantages; slides offer versatility, while rails offer ultra-high precision.

Internal Link Suggestions

Linear rails

Linear motion systems

Outbound Link Suggestions

Igus Linear Slide Catalog

THK Slide Systems

Parker Precision Stages