Comprehensive Outline

| Main Sections | Detailed Coverage |

|---|---|

| Linear Rail Slides Overview | Definition, industrial relevance |

| Evolution of Linear Motion | From sliding guides to rolling systems |

| Linear Rail Slides Fundamentals | Motion principles and mechanics |

| Core Components | Rail, carriage, rolling elements |

| Materials and Surface Treatment | Steel grades, coatings |

| Load and Moment Handling | Static, dynamic, and torque loads |

| Precision and Accuracy | Repeatability, rigidity |

| Types of Linear Rail Slides | Ball, roller, miniature |

| Linear Rail Slides vs Traditional Guides | Performance comparison |

| Installation Requirements | Mounting and base preparation |

| Alignment and Preload | Accuracy optimization |

| Lubrication Systems | Grease, oil, auto-lube |

| Maintenance and Service Life | Inspection and wear control |

| Environmental Adaptability | Dust, moisture, temperature |

| Noise and Vibration Reduction | Smooth motion benefits |

| Linear Rail Slides in Automation | Robotics, pick-and-place |

| CNC and Machine Tools | Cutting accuracy |

| Medical and Laboratory Equipment | Clean and precise motion |

| Semiconductor and Electronics | Cleanroom compatibility |

| Heavy Industry Applications | Load-intensive machinery |

| Selecting the Right Linear Rail Slides | Technical considerations |

| Common Selection Errors | Oversizing and misapplication |

| Cost Efficiency and ROI | Long-term benefits |

| YH Linear Linear Rail Slides | Brand strengths and solutions |

| Future Trends | Smart motion systems |

Introduction

Linear rail slides have become a cornerstone of modern mechanical design. Wherever precise, smooth, and repeatable linear motion is required, these systems quietly perform their role with remarkable consistency. From CNC machining centers to automated production lines, linear rail slides ensure that movement remains controlled, accurate, and reliable.

At YH Linear, years of hands-on experience in linear motion technology have shown that the right linear rail slides can dramatically improve machine performance. When manufacturers upgrade from traditional guides to advanced linear rail slides, they often notice immediate gains in accuracy, speed, and operational stability. This article explores why linear rail slides are so critical and how they continue to shape industrial innovation.

Linear Rail Slides

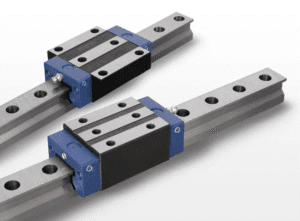

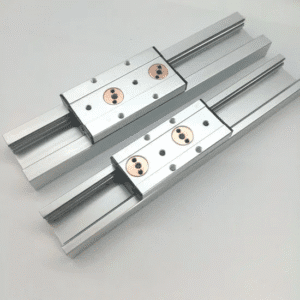

Linear rail slides are precision mechanical systems designed to guide moving components along a straight path using rolling contact. Unlike plain slideways, which rely on surface-to-surface friction, linear rail slides use balls or rollers that circulate inside the carriage. This design significantly reduces friction while increasing load capacity and motion accuracy.

One of the defining features of linear rail slides is their ability to handle loads from multiple directions. Vertical loads, lateral forces, and moment loads are all supported simultaneously. As a result, machine designers gain greater freedom and flexibility.

At YH Linear, linear rail slides are engineered with strict quality control, ensuring consistent performance across demanding industrial environments. These systems do more than guide motion; they provide confidence in every movement cycle.

The Evolution of Linear Motion Technology

Before linear rail slides became common, machines relied on dovetail guides and plain bearings. While functional, these systems suffered from high friction, uneven wear, and frequent maintenance needs.

The introduction of rolling-element technology marked a turning point. By replacing sliding contact with rolling contact, linear rail slides transformed motion efficiency. Machines became faster, more accurate, and easier to maintain.

Today, linear rail slides represent the culmination of decades of engineering refinement. Precision grinding, advanced materials, and optimized bearing circulation all contribute to their superior performance. This evolution continues, driven by automation and smart manufacturing demands.

Engineering Principles Behind Linear Rail Slides

The core principle behind linear rail slides is rolling friction reduction. Balls or rollers move smoothly along hardened raceways, distributing loads evenly and minimizing resistance.

Another essential principle is preload. By applying controlled internal pressure, linear rail slides eliminate clearance. This improves rigidity and repeatability, especially in high-precision applications such as CNC machining.

Thermal stability also matters. Well-designed linear rail slides compensate for expansion and contraction, maintaining accuracy even under temperature changes. These principles work together to deliver smooth, predictable motion.

Core Components of Linear Rail Slides

A typical linear rail slide system consists of a rail, a carriage, rolling elements, seals, and lubrication channels.

The rail is precision-ground from hardened steel to ensure straightness and durability. The carriage houses the rolling elements and redistributes load across the rail. Balls or rollers circulate continuously, maintaining constant contact.

Seals protect internal components from dust and debris, while lubrication ports ensure smooth long-term operation. At YH Linear, each component is manufactured and assembled with strict tolerances to guarantee performance consistency.

Materials and Surface Treatments

Material selection plays a crucial role in the durability of linear rail slides. High-carbon alloy steel is commonly used due to its strength and wear resistance.

Surface treatments such as black oxide, chrome plating, or special coatings enhance corrosion resistance. These treatments are especially important in humid or chemically aggressive environments.

YH Linear offers linear rail slides with tailored surface options, allowing customers to match material properties with application requirements.

Load Capacity and Moment Handling

Linear rail slides are designed to handle complex load conditions. In addition to vertical loads, they support lateral forces and twisting moments.

Roller-type linear rail slides excel in heavy-load applications due to their line contact design. Ball-type systems, while lighter, still provide impressive load capacity and high-speed performance.

Proper load calculation ensures optimal rail selection. Oversizing increases cost, while undersizing risks premature failure. YH Linear provides technical support to help customers select the ideal solution.

Precision, Accuracy, and Repeatability

Precision is a defining advantage of linear rail slides. High-quality systems offer micron-level accuracy and exceptional repeatability.

This precision is achieved through tight manufacturing tolerances, preload control, and consistent lubrication. As a result, machines maintain accuracy over long production runs.

For industries where precision defines product quality, linear rail slides are indispensable.

Types of Linear Rail Slides

Linear rail slides are available in several configurations. Ball-type systems are widely used for automation and light machining. Roller-type systems provide higher rigidity and load capacity.

Miniature linear rail slides serve compact devices such as medical instruments and electronic equipment. Each type addresses specific performance needs.

YH Linear offers a comprehensive range of linear rail slides, ensuring compatibility with diverse applications.

Installation and Alignment Best Practices

Correct installation is essential for maximizing the performance of linear rail slides. Mounting surfaces must be flat, rigid, and clean.

Alignment ensures even load distribution and smooth motion. Misalignment increases wear and reduces accuracy. Following manufacturer guidelines is critical.

YH Linear provides installation guidance to help customers achieve optimal results.

Applications of Linear Rail Slides

Linear rail slides are used across countless industries. In automation, they enable smooth pick-and-place operations. In CNC machines, they ensure cutting accuracy.

Medical equipment relies on linear rail slides for quiet, precise movement. Semiconductor manufacturing demands clean, vibration-free motion.

From light-duty devices to heavy industrial systems, linear rail slides adapt effortlessly.

YH Linear Linear Rail Slides

YH Linear specializes in high-performance linear rail slides designed for reliability and precision. Each product reflects deep industry knowledge and rigorous quality standards.

By combining advanced manufacturing with practical engineering insight, YH Linear delivers solutions that perform consistently in real-world conditions. Customers benefit from dependable motion systems and responsive technical support.

Choosing YH Linear means investing in long-term performance and engineering confidence.

Future Trends in Linear Rail Slides

The future of linear rail slides lies in smart integration. Sensors embedded within rails can monitor load, temperature, and wear.

Lightweight materials and improved coatings continue to enhance efficiency. As automation expands, demand for intelligent, maintenance-friendly linear rail slides will grow.

YH Linear remains committed to innovation, ensuring customers stay ahead of industry trends.

FAQs

What are linear rail slides used for?

Linear rail slides guide components in straight-line motion with high accuracy and low friction.

How do linear rail slides differ from traditional guides?

They use rolling elements instead of sliding contact, reducing friction and wear.

Are linear rail slides suitable for heavy loads?

Yes, especially roller-type systems designed for high rigidity.

Do linear rail slides require regular maintenance?

Yes, proper lubrication and inspection extend service life.

Can linear rail slides operate in harsh environments?

With proper sealing and coatings, they perform well in challenging conditions.

Why choose YH Linear linear rail slides?

YH Linear combines quality manufacturing, technical expertise, and reliable performance.

Conclusion

Linear rail slides are essential to modern precision motion systems. Their ability to deliver smooth, accurate, and reliable movement has transformed industrial design. From automation to medical technology, they provide unmatched performance.

With proven expertise and a commitment to quality, YH Linear continues to support industries worldwide with dependable linear rail slide solutions. Investing in the right system today ensures precision and productivity tomorrow.

Suggested Internal Links

YH Linear product catalog for linear guides

Suggested Outbound Links

Industrial linear motion standards organizations

Automation and CNC engineering resources