Introduction

For anyone working with CNC routers, achieving smooth, precise, and reliable linear motion is critical. Linear guides are a fundamental part of CNC machines, ensuring that the cutting tool moves accurately along the X, Y, and Z axes.

CNC router linear guides are specifically designed to handle the demands of high-speed machining while maintaining accuracy and rigidity. Selecting the right guide can dramatically improve cutting quality, machine longevity, and efficiency.

This article explores what CNC router linear guides are, their types, materials, advantages, applications, and selection tips for both hobbyist and professional setups.

What Are CNC Router Linear Guides?

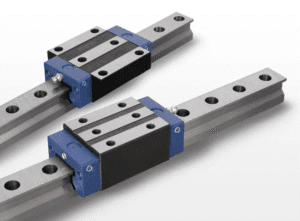

CNC router linear guides are precision components that provide linear motion support for the moving parts of a CNC router. They consist of:

Rails: Precision-machined tracks that define the motion path

Carriages or Blocks: Bearing assemblies that slide along the rail

Rolling or Sliding Elements: Ball bearings or rollers that reduce friction

These guides ensure the CNC router operates smoothly, accurately, and consistently, even under heavy cutting loads.

Why CNC Routers Need Linear Guides

CNC routers operate at high speeds with cutting tools applying significant forces. Without proper linear guidance, issues like vibration, backlash, and uneven cutting can occur. Linear guides provide:

Precision: Accurate motion along all axes

Rigidity: Reduces deflection under cutting forces

Smooth Motion: Minimal friction for consistent feed rates

Longevity: Durable guidance system that withstands wear

For both hobby CNC routers and professional-grade machines, linear guides are essential for quality results.

Types of CNC Router Linear Guides

1. Ball Bearing Linear Guides

Use recirculating steel balls inside the carriage

Offer smooth motion and low friction

High accuracy, suitable for fast-moving axes

Applications: High-speed CNC routers, lightweight aluminum CNC machines

2. Roller Bearing Linear Guides

Cylindrical or needle rollers replace balls

Provide higher load capacity and rigidity

Ideal for heavy-duty CNC routers

Applications: Large-frame routers, heavy materials like wood, metal, or composites

3. Round Shaft Linear Guides

Cylindrical shafts with bushings or linear bearings

Cost-effective and compact

Moderate load capacity and accuracy

Applications: Hobby CNC routers, DIY machines, light-duty cutting

4. Profiled Linear Rails

Square or rectangular rails with precision carriages

High rigidity and multi-directional load support

Long service life, suitable for professional CNC routers

Applications: Industrial CNC routers, 3-axis and 5-axis machines

Materials Used in CNC Router Linear Guides

Hardened Steel: High durability and wear resistance

Stainless Steel: Corrosion resistance for humid or dusty environments

Aluminum Rails: Lightweight, used in compact or hobby machines

Polymer Bearings or Inserts: Low-cost option for light-duty routers

Material choice affects load capacity, smoothness, and maintenance needs.

Advantages of CNC Router Linear Guides

High Precision: Minimal play ensures accurate cuts

Smooth Motion: Rolling bearings reduce friction

Load Distribution: Supports axial, radial, and moment loads

High Speed: Suitable for fast feed rates

Durability: Long-lasting even under continuous operation

Using high-quality linear guides can dramatically improve cut quality and machine reliability.

Applications of CNC Router Linear Guides

CNC router linear guides are used in:

Woodworking CNC Routers: Accurate milling, engraving, and cutting

Metalworking CNC Routers: Aluminum, brass, or soft steel cutting

Composite Cutting Machines: Carbon fiber, plastics, and acrylics

Hobby and DIY CNC Routers: Affordable precision for home projects

Industrial Production Lines: Multi-axis CNC systems for mass production

CNC Router Linear Guides vs. V-Slot or Gantry Wheels

| Feature | CNC Linear Guide | V-Slot / Gantry Wheels |

|---|---|---|

| Precision | High | Medium |

| Load Capacity | High | Moderate |

| Friction | Low | Higher |

| Rigidity | High | Medium |

| Maintenance | Moderate | Low |

| Best Use | Professional & heavy-duty routers | Hobby and lightweight machines |

For high-precision cutting, linear guides outperform wheel-based systems in accuracy, rigidity, and load capacity.

How to Choose CNC Router Linear Guides

Determine Machine Size: Larger frames require more rigid rails

Evaluate Load and Cutting Forces: Heavy materials need roller or profiled guides

Consider Precision Needs: Fine engraving vs rough cutting affects guide selection

Assess Travel Length and Space: Ensure the rail fits the CNC gantry

Budget Considerations: Hobby machines can use round shaft guides, industrial routers benefit from profiled linear rails

Environmental Factors: Dust, humidity, or metal debris may require stainless steel or sealed guides

Selecting the right guide ensures consistent, accurate, and long-lasting CNC operation.

Maintenance Tips for CNC Router Linear Guides

Clean regularly to remove dust, wood chips, or metal shavings

Lubricate according to manufacturer specifications

Inspect bearings and rails for wear or misalignment

Avoid overloading to prevent premature wear or bending

Proper maintenance ensures smooth motion and extended service life.

Frequently Asked Questions (FAQs)

1. Can I use cheap linear guides for a CNC router?

Yes, for hobby or light-duty CNC routers. Industrial or professional-grade machines require high-quality profiled or roller guides.

2. How long do CNC router linear guides last?

With proper maintenance, professional-grade linear guides can last 5–10+ years, depending on usage and environment.

3. Are linear guides better than wheels for CNC routers?

Yes, linear guides provide higher precision, rigidity, and load capacity, especially for heavy-duty or high-speed cutting.

4. Do CNC router linear guides need lubrication?

Yes, regular lubrication is necessary to maintain smooth motion and prevent wear.

5. Can linear guides handle dust from cutting wood?

Yes, but proper sealing, wipers, or covers are recommended to prevent debris from entering the bearing system.

Conclusion

CNC router linear guides are crucial for achieving precise, smooth, and reliable motion in both hobby and professional CNC machines. Choosing the right guide type, material, and size ensures accurate cutting, high rigidity, and long service life.

From round shaft guides for DIY projects to roller or profiled linear guides for industrial machines, understanding the differences and maintenance requirements will help you get the best performance from your CNC router.