Introduction

As industrial equipment continues to demand higher precision, greater load capacity, and improved stability, the square linear guide has become a core component in modern linear motion systems. Widely used in CNC machine tools, automation equipment, robotics, and heavy-duty machinery, square linear guides offer exceptional rigidity, accuracy, and durability.

Compared with compact or round linear guides, square linear guides are designed to handle multi-directional loads and high moments, making them ideal for applications where precision and structural stiffness are critical.

This article provides a comprehensive explanation of square linear guides, including their structure, working principles, types, advantages, applications, selection criteria, installation methods, and maintenance practices.

What Is a Square Linear Guide?

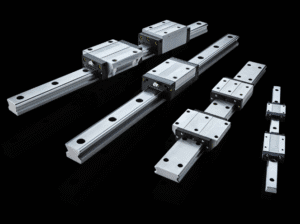

A square linear guide is a type of profiled linear motion guide characterized by its square or rectangular carriage block. It consists of:

A precision-ground rail

A square-shaped carriage (block)

Rolling elements, typically steel balls or rollers

Seals, retainers, and lubrication paths

The square carriage design allows the guide to support loads from multiple directions (radial, reverse radial, and lateral), making it highly versatile for complex mechanical systems.

How a Square Linear Guide Works

Square linear guides operate using recirculating rolling elements:

The carriage moves along the rail.

Steel balls or rollers roll between the rail raceways and carriage grooves.

Rolling elements circulate inside the carriage through return paths.

Load is evenly distributed across multiple contact points.

Friction is minimized while rigidity and positioning accuracy are maximized.

This rolling mechanism enables smooth, precise, and repeatable linear motion even under high loads.

Main Components of a Square Linear Guide

1. Linear Rail

Made of hardened, precision-ground steel

Provides a straight and rigid guiding path

Designed to withstand high loads and wear

2. Square Carriage (Block)

Rectangular or square profile for high stiffness

Houses rolling elements and return channels

Supports multi-directional and moment loads

3. Rolling Elements

Steel balls or cylindrical rollers

Reduce friction and distribute loads evenly

Enable high-speed and high-precision movement

4. End Caps and Retainers

Guide rolling elements through circulation paths

Ensure smooth and continuous motion

5. Seals and Wipers

Prevent dust, debris, and liquid ingress

Extend the service life of the guide

6. Lubrication System

Integrated grease or oil channels

Reduces wear and ensures smooth operation

Types of Square Linear Guides

1. Ball-Type Square Linear Guide

Uses recirculating steel balls

Low friction and high speed

Suitable for CNC machines, automation systems, and pick-and-place equipment

2. Roller-Type Square Linear Guide

Uses cylindrical rollers instead of balls

Higher rigidity and load capacity

Ideal for heavy-duty CNC machines and gantry systems

3. Heavy-Load Square Linear Guide

Larger rail and block size

Designed for high static and dynamic loads

Used in large machining centers and industrial presses

4. Miniature Square Linear Guide

Compact square block design

High precision in limited space

Suitable for medical devices, electronics, and laboratory automation

Materials and Surface Treatments

High-Carbon Hardened Steel – Superior strength and wear resistance

Stainless Steel – Corrosion resistance for harsh or clean environments

Surface Treatments:

Induction hardening

Black oxide coating

Chrome plating

Material selection depends on load conditions, environmental exposure, and lifespan requirements.

Advantages of Square Linear Guides

High Rigidity – Square block design resists deformation

Multi-Directional Load Support – Handles radial, lateral, and moment loads

High Precision and Repeatability

Smooth, Low-Friction Motion

High Load Capacity

Long Service Life

Easy Integration with CNC and Automation Systems

Applications of Square Linear Guides

CNC Machine Tools – Milling machines, lathes, and machining centers

Industrial Automation – Assembly lines and transfer systems

Robotics – Linear axes and positioning stages

Gantry Systems – High-load and long-travel applications

Packaging Machinery – High-speed precision movement

Semiconductor Equipment – Clean and accurate motion control

Square Linear Guide vs. Other Linear Guides

| Feature | Square Linear Guide | Round Linear Guide | Miniature Guide |

|---|---|---|---|

| Load Capacity | High | Medium | Low |

| Rigidity | Very High | Medium | Medium |

| Multi-Directional Load | Excellent | Limited | Moderate |

| Precision | High | Medium | High |

| Common Use | CNC, automation | Light machinery | Compact devices |

Square linear guides are preferred for high-load and high-precision applications.

How to Choose the Right Square Linear Guide

Load Capacity – Static, dynamic, and moment loads

Accuracy Requirements – Positioning precision and repeatability

Travel Length – Required stroke and rail length

Speed and Acceleration

Environmental Conditions – Dust, moisture, chemicals

Mounting Space and Structure

Maintenance Accessibility

Correct selection ensures maximum performance and long-term reliability.

Installation Best Practices

Ensure mounting surfaces are flat and rigid

Align rails carefully to avoid uneven load distribution

Tighten fasteners to specified torque values

Lubricate the guide before operation

Perform test runs at low speed before full load operation

Proper installation directly affects accuracy, lifespan, and smooth operation.

Maintenance and Care

Clean rails and blocks regularly

Check seals and wipers for damage

Re-lubricate according to usage conditions

Inspect for abnormal noise or vibration

Routine maintenance ensures consistent performance and extended service life.

Future Trends in Square Linear Guide Technology

Higher load capacity with compact designs

Advanced surface coatings for extreme environments

Maintenance-free or long-life lubrication systems

Integration with smart monitoring sensors

Greater precision for automated manufacturing

Frequently Asked Questions (FAQs)

1. What is a square linear guide used for?

It provides precise and stable linear motion in CNC machines, automation systems, and industrial equipment.

2. Why choose a square linear guide instead of a round guide?

Square linear guides offer higher rigidity and better multi-directional load support.

3. Can square linear guides handle heavy loads?

Yes, especially roller-type and heavy-load square guides.

4. Do square linear guides require lubrication?

Yes, proper lubrication is essential for smooth motion and long service life.

5. Are square linear guides suitable for high-speed motion?

Yes, ball-type square guides are ideal for high-speed and high-precision applications.

Conclusion

Square linear guides are essential components for high-precision, high-rigidity linear motion systems. Their robust square block design, excellent load-bearing capability, and smooth rolling motion make them indispensable in CNC machining, industrial automation, robotics, and heavy machinery.

With proper selection, installation, and maintenance, square linear guides deliver long-term accuracy, reliability, and efficiency in demanding industrial environments.