Introduction

In modern machinery and automation systems, precision, smooth motion, and reliability are crucial. One of the key components that enable these characteristics is the linear guide, also known as a linear motion guide or linear slide.

A linear guide provides precise linear movement for machines, reducing friction and wear while improving accuracy and load-carrying capacity. From CNC machines and 3D printers to industrial robots and packaging equipment, linear guides are essential in countless industrial applications.

Definition of a Linear Guide

A linear guide is a mechanical device designed to allow smooth, controlled, and accurate linear motion along a straight path. Unlike traditional sliding systems, linear guides use rolling elements, such as balls or rollers, to minimize friction, enabling high precision, efficiency, and long service life.

The main purpose of a linear guide is to support and guide moving components, ensuring their motion is consistent, stable, and predictable.

Structure of a Linear Guide

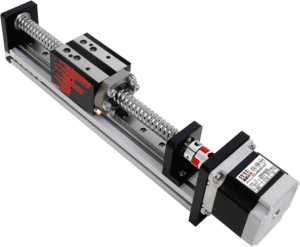

A typical linear guide system consists of three main components:

Rail (Track)

A rigid, precisely machined steel or aluminum rail.

Provides a smooth surface for rolling elements to move along.

Designed to bear loads and resist deformation under stress.

Carriage (Slider or Block)

Moves along the rail with minimal friction.

Houses the rolling elements, such as ball bearings or rollers.

Supports the moving part of the machinery or workpiece.

Rolling Elements

Balls or cylindrical rollers recirculate inside the carriage.

Reduce friction by transforming sliding motion into rolling motion.

Provide high precision, rigidity, and load capacity.

Additional components can include end caps, seals, and lubrication systems to ensure smooth operation and prevent contamination.

How Does a Linear Guide Work?

Linear guides operate on the principle of rolling friction.

The carriage slides along the rail, but instead of sliding directly on the surface, balls or rollers roll between grooves in the rail and carriage.

This rolling motion drastically reduces friction compared to traditional sliding motion.

The rolling elements circulate continuously within the carriage, providing consistent smooth movement and high positional accuracy.

Precision machining of the rail and carriage ensures minimal deflection, high rigidity, and uniform load distribution.

This mechanism allows linear guides to carry heavy loads while maintaining high precision and low wear over extended periods.

Types of Linear Guides

Linear guides come in different configurations, each suitable for specific applications:

Ball-Type Linear Guides

Uses recirculating ball bearings.

High precision and smooth motion.

Commonly used in CNC machines and industrial automation.

Roller-Type Linear Guides

Uses cylindrical rollers instead of balls.

Can carry higher loads and offers higher rigidity.

Suitable for heavy-duty machining or industrial presses.

Profile Rail Guides

Features a compact rail and carriage with recirculating elements.

Allows for multi-directional load support.

Popular in robotics and precision assembly equipment.

Miniature Linear Guides

Smaller version for light loads and compact designs.

Used in medical devices, optics, and small automation equipment.

Advantages of Linear Guides

Linear guides offer multiple benefits over traditional sliding or plain bearing systems:

High Precision and Accuracy – Provides consistent linear motion with minimal deviation.

Low Friction – Rolling elements reduce friction and wear, improving efficiency.

High Load Capacity – Supports heavy loads relative to its size.

Long Service Life – Reduced wear and optimized lubrication increase durability.

Smooth and Quiet Operation – Rolling motion is smoother than sliding.

Easy Maintenance – Many linear guides come with integrated lubrication systems.

Applications of Linear Guides

Linear guides are used across industrial automation, robotics, and machinery. Common applications include:

CNC Machines – Precision cutting, milling, and engraving.

3D Printers – Smooth and accurate motion for printing heads.

Robotics – Linear actuators for pick-and-place operations.

Medical Devices – Lab automation and diagnostic equipment.

Semiconductor Manufacturing – High-precision stages for wafer handling.

Packaging Equipment – Smooth motion for filling, labeling, and assembly.

Essentially, any industry that requires precise, repeatable linear movement benefits from linear guides.

How to Choose a Linear Guide

When selecting a linear guide system, consider the following:

Load Capacity – Ensure the guide can support both static and dynamic loads.

Accuracy Requirements – Higher precision applications require higher quality rail machining and smaller clearances.

Travel Length – Choose rails long enough for the required motion.

Environment – Sealed or stainless-steel guides are recommended for dusty, humid, or corrosive conditions.

Speed and Acceleration – Ensure the guide can handle operational speeds without vibration or wear.

Maintenance – Check for integrated lubrication systems or ease of re-lubrication.

Frequently Asked Questions (FAQs)

1. What is the difference between a linear guide and a linear bearing?

A linear guide includes a rail, carriage, and rolling elements, designed for precise linear motion. A linear bearing is typically a simpler sleeve or bushing that allows sliding motion but with higher friction and lower accuracy.

2. Can linear guides carry heavy loads?

Yes. Roller-type and profile rail guides can carry significant loads and are often used in industrial presses and CNC machines.

3. Do linear guides require lubrication?

Yes. Most linear guides have either manual grease lubrication points or pre-lubricated recirculating systems to ensure smooth motion and long life.

4. What materials are linear guides made from?

Rails and carriages are commonly made from hardened steel for high strength, though stainless steel or aluminum is used in corrosive or lightweight applications.

5. Where are linear guides commonly used?

They are used in CNC machining, 3D printing, robotics, lab automation, semiconductor manufacturing, and packaging equipment—essentially any application requiring precise linear motion.

Conclusion

A linear guide is an essential component in modern machinery, enabling smooth, accurate, and reliable linear motion.

Whether used in precision CNC machines, robotics, or 3D printers, linear guides improve performance, reduce wear, and ensure consistent operation. Choosing the right linear guide system depends on load, speed, accuracy, and environment considerations.

With advancements in design and materials, linear guides continue to be a critical technology in industrial automation and precision engineering.